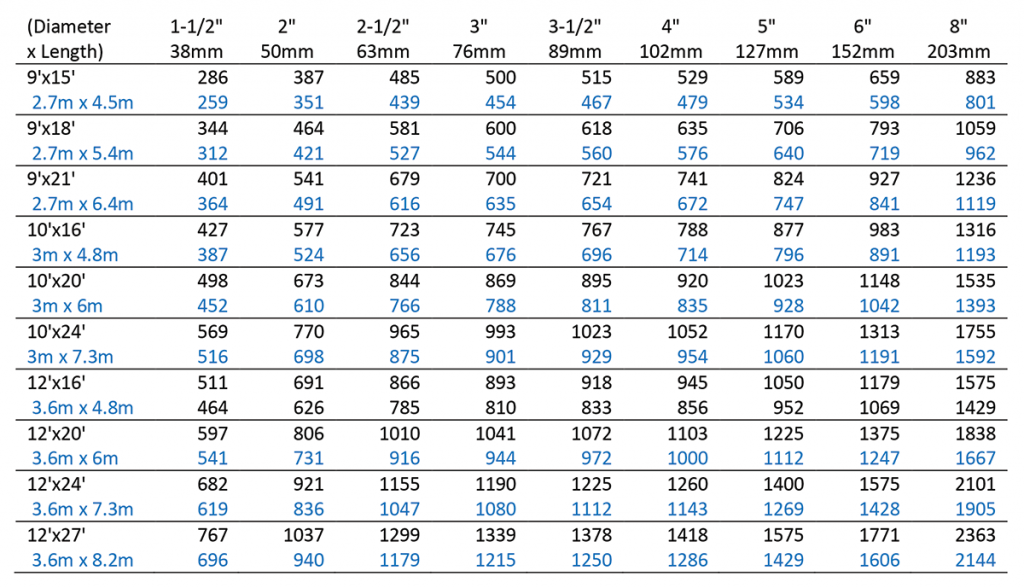

CSI™ Rotary Breaker

Top numbers are short tons per hour, bottom are metric tons per hour.

Tonnages are based upon 50 lbs. per cubic foot coal

* This chart is meant only to be a general guide. Many other factors such as HGI, feed lump size, flow chart, etc.,

must be taken into account prior to sizing a rotary breaker. Please always call Elgin and

discuss your project with a rotary breaker specialist in order to confirm your rotary breaker selection.

Check out our Rotary Breaker in action!

Overview

Features

Resources

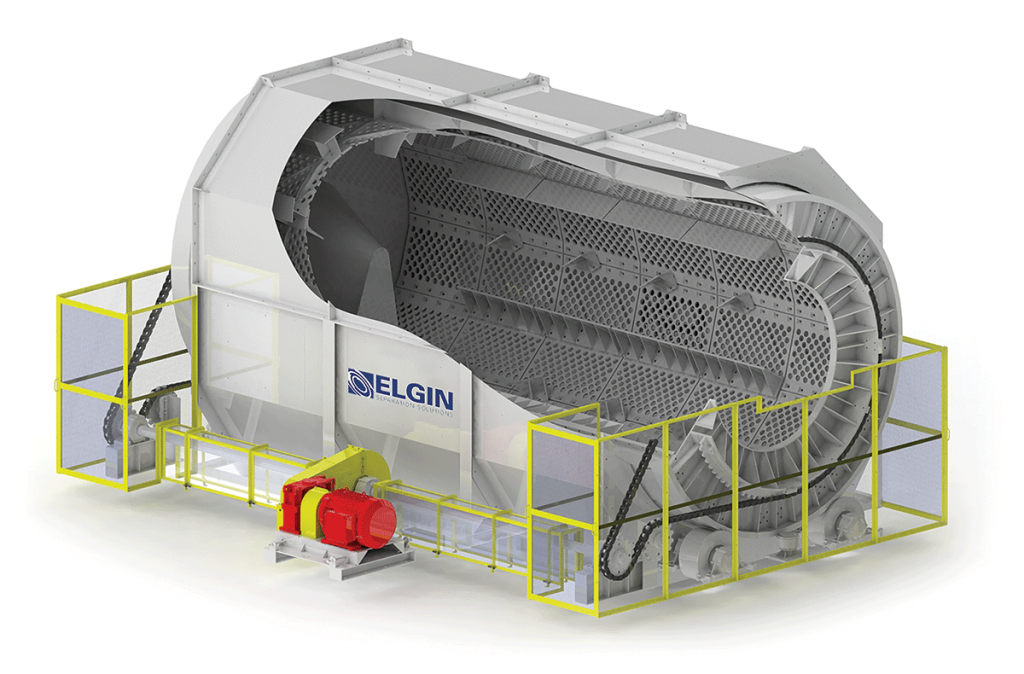

The Rotary Breaker is designed to process feed materials such as coal, alumina, oil sands, aluminum dross and others for further processing.

Featuring dual or single end drives, Elgin Rotary Breakers lift and drop feed material several times as it travels through the drum to size the material and scalp undesirable material. The desirable sized material passes through the screen perforations and into the product hopper where it is collected for further processing or use. The undesirable material traverses through the breaker and out the discharge end where it is collected for disposal.

- Available in dual or single end drive.

- Tires are manufactured from an endless ring forging.

- Trunnions are manufactured from 4140 steel.

- Spreader beams with stiffening gussets are machined to a common length and the end bell mounting pads are machined to a common height to decrease axial runout.

- Non-overlapping cast manganese or wear alloy breaker plates allow for independent replacement.

- Independent adjustable plows.

- Inline lifters to increase the volume of material lifted and processed through the drum.