RUN-OF-RIVER INTAKES

Run-of-river refers to a water capture method that involves little or no water storage. Most commonly found in high elevations, these intake systems are attractive for their minimal environmental impact and low civil installation cost.

A passive run-of-river intake typically includes a small dam and corresponding head pond – a perfect fit for Elgin’s Coanda screen. When water depths are more consistent, a side intake gallery can be utilized to further simplify the intake.

COANDA SCREENS

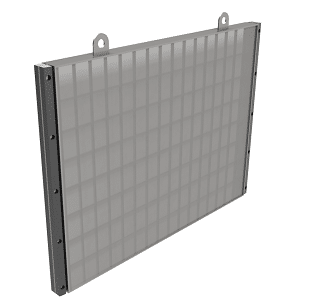

LET GRAVITY DO THE WORK – Coanda screens are spillway screens that use the gravity drop of the water to keep the screen clean. The approach plate uses the Coanda effect to accelerate water toward the screen – we let gravity do what it does best! Tilted wedge wire panels are below the approach plate to slice the bottom layer of this fast-moving water. The faster the water, the more efficient the screen is, so Elgin has optimized designs that are the lowest maintenance screens on the market. Check out our standard profiles.

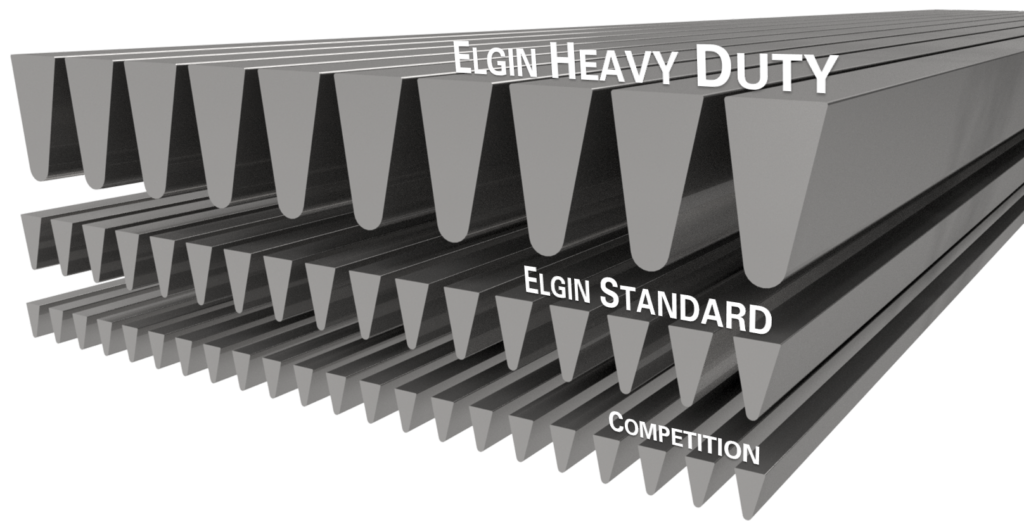

GO BIG OR GO HOME – Elgin’s screens are the strongest in the world. The backbone is our wedge wire. While our competition uses light duty wedge wire, Elgin’s standard duty screen wire is nearly 6x stronger, and our heavy duty wire is over 100x stronger. Elgin also TIG welds the screen media, giving us a tremendous weld strength that is critical for the lateral loads that Coanda screen wires experience.