Choosing the Right Screw Conveyor for Your Operations

When selecting the right screw conveyor for your operations, it is important to evaluate available options for maximum performance in material conveyance. At Elgin, we work closely with our customers to help them choose the right screw conveyor for the type of material being processed.

Used to convey bulk materials from one part of a process to another, conveyors are available in a wide range of sizes, lengths, configurations, and materials of construction. Compact in design and the ability to handle a wide variety of material makes them a good choice for operations. In this article, we will focus on two types of conveyors, shafted and shaftless.

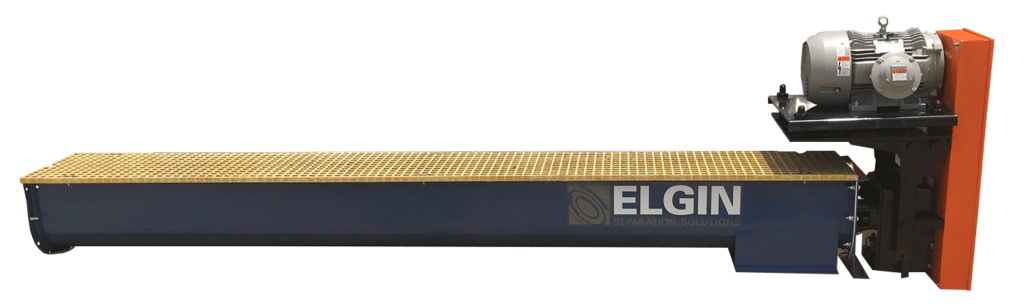

Shafted Screw Conveyors

Shafted Screw Conveyors have a solid shaft that goes through the flighting of the screw. The shaft holds the flighting off the bottom of the trough. Benefits of this conveyor are that they can be of longer length, there is no need for a liner and the associated maintenance, and they can run at higher RPMs since there is no concern about liner wear. The traditional screw conveyor is generally considered low maintenance.

Advantages:

- Ideal for conveying dry to semi-fluid bulk materials – free flowing to sluggish

- Cost-effective when compared to other conveying devices such as belt conveyors

- Efficiently distributes bulk materials to various locations using multiple inlet and discharge points

- Totally enclosed for dusty, corrosive or hazardous environments

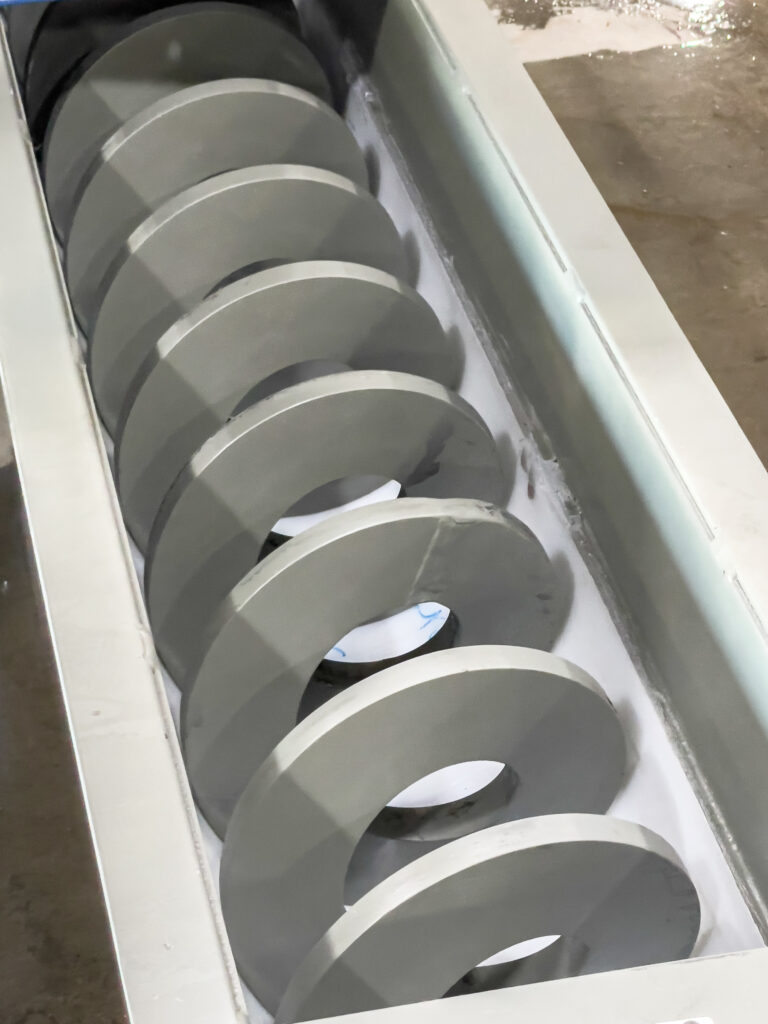

Shaftless Screw Conveyors

Shaftless Screw Conveyors’ simple, pipeless design employs fewer parts than conventional shafted-screw conveyors, reducing lifetime maintenance costs. It enables higher trough loading and lower RPMs, maximizing the volume of materials conveyed. Shaftless Screw Conveyors eliminates jamming and buildup typical in shafted-screw conveyors for greater uptime, higher efficiency, and lower maintenance. By eliminating hanger and end bearings to reduce maintenance and increase efficiency, the shaftless conveyor enables direct transfer to another conveyor.

Advantages:

- Ideal for handling sticky and sluggish bulk materials

- Improved conveying efficiency when compared to other types of conveyors

- Internal bearings are eliminated

- No hanger bearing supports

- No center pipe that causes product build up

- Full product clean out

- Replaceable trough liner

- High wear properties

Disadvantages of shafted conveyors include obstruction of flow at hanger bearing sections and low fill capacity due to the bearing connections. Shaftless conveyors require reinforcements along the length of the unit due to compression of the load in long runs with high volume. Additionally, replacing the liner can be difficult if located in high placement or tight locations.

As screw conveyors are a standard “go to” in material handling operations in both shafted and shaftless forms, the final choice typically comes down to location, desired flow rate, and type of material being processed. If you need a Shaftless or Shafted Screw Conveyor for your operations, contact a representative at Elgin.

When selecting the right screw conveyor for your operations, it is important to evaluate available options for maximum performance in material conveyance. At Elgin, we work closely with our customers to help them choose the right screw conveyor for the type of material being processed.

Used to convey bulk materials from one part of a process to another, conveyors are available in a wide range of sizes, lengths, configurations, and materials of construction. Compact in design and the ability to handle a wide variety of material makes them a good choice for operations. In this article, we will focus on two types of conveyors, shafted and shaftless.

Shafted Screw Conveyors

Shafted Screw Conveyors have a solid shaft that goes through the flighting of the screw. The shaft holds the flighting off the bottom of the trough. Benefits of this conveyor are that they can be of longer length, there is no need for a liner and the associated maintenance, and they can run at higher RPMs since there is no concern about liner wear. The traditional screw conveyor is generally considered low maintenance.

Advantages:

- Ideal for conveying dry to semi-fluid bulk materials – free flowing to sluggish

- Cost-effective when compared to other conveying devices such as belt conveyors

- Efficiently distributes bulk materials to various locations using multiple inlet and discharge points

- Totally enclosed for dusty, corrosive or hazardous environments

Shaftless Screw Conveyors

Shaftless Screw Conveyors’ simple, pipeless design employs fewer parts than conventional shafted-screw conveyors, reducing lifetime maintenance costs. It enables higher trough loading and lower RPMs, maximizing the volume of materials conveyed. Shaftless Screw Conveyors eliminates jamming and buildup typical in shafted-screw conveyors for greater uptime, higher efficiency, and lower maintenance. By eliminating hanger and end bearings to reduce maintenance and increase efficiency, the shaftless conveyor enables direct transfer to another conveyor.

Advantages:

- Ideal for handling sticky and sluggish bulk materials

- Improved conveying efficiency when compared to other types of conveyors

- Internal bearings are eliminated

- No hanger bearing supports

- No center pipe that causes product build up

- Full product clean out

- Replaceable trough liner

- High wear properties

Disadvantages of shafted conveyors include obstruction of flow at hanger bearing sections and low fill capacity due to the bearing connections. Shaftless conveyors require reinforcements along the length of the unit due to compression of the load in long runs with high volume. Additionally, replacing the liner can be difficult if located in high placement or tight locations.

As screw conveyors are a standard “go to” in material handling operations in both shafted and shaftless forms, the final choice typically comes down to location, desired flow rate, and type of material being processed. If you need a Shaftless or Shafted Screw Conveyor for your operations, contact a representative at Elgin.

The inside of Elgin’s Shafted Screw Conveyor

Contact an Elgin Representative today to learn more about our different Screw Conveyor options.

The inside of Elgin’s Shaftless Screw Conveyor