RotoVeyor Auger™ Screw Conveyors

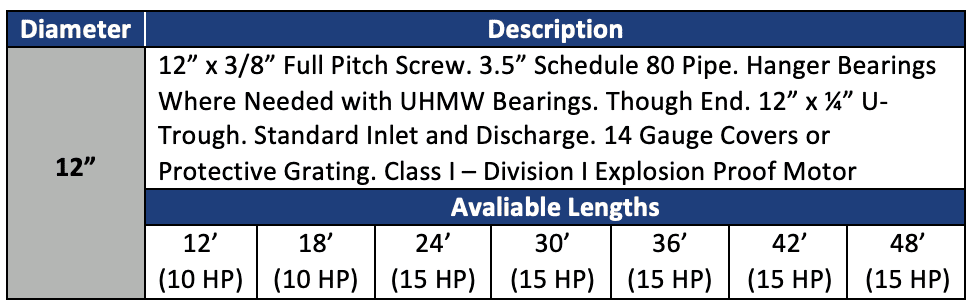

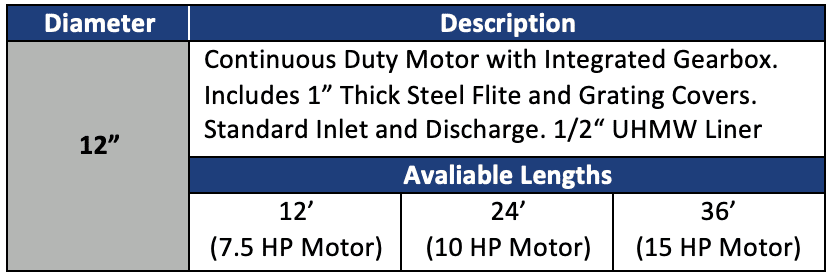

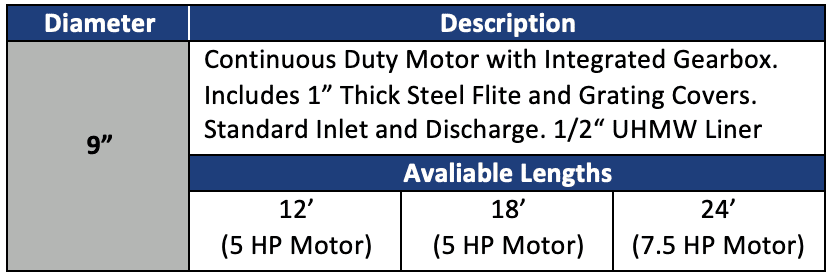

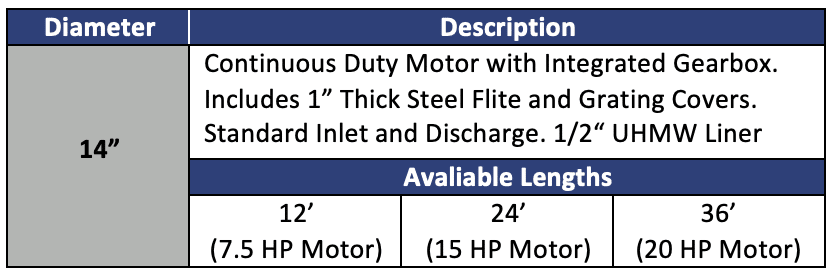

Shafted Screw Conveyor Specifications

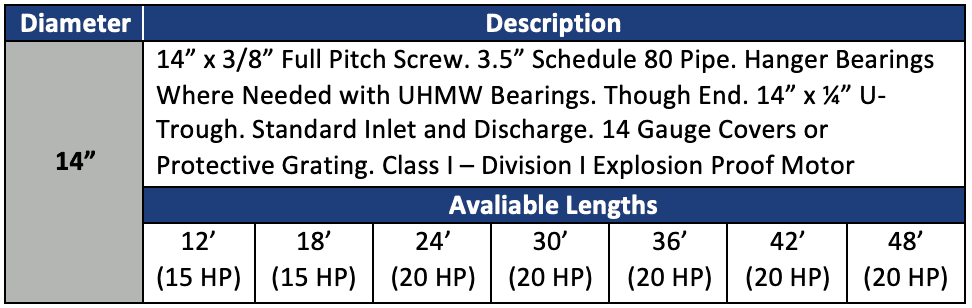

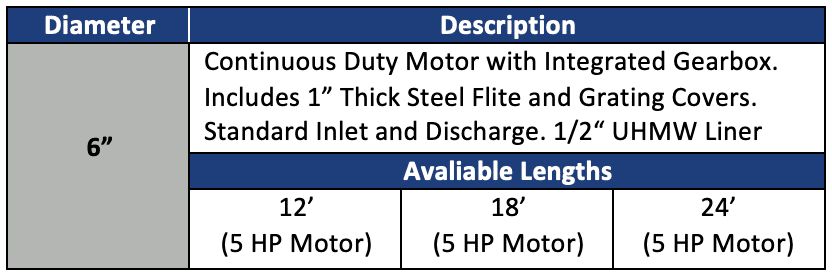

Shaftless Screw Conveyor Specifications

Overview

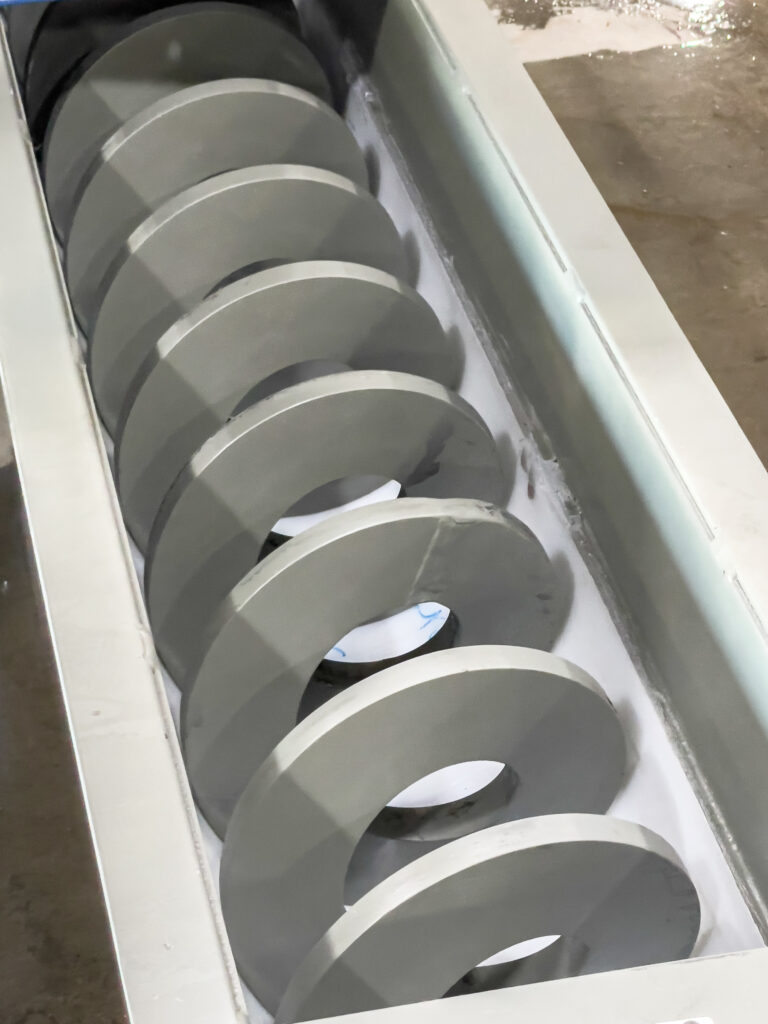

Shafted Screw Conveyors

Shafted Screw Conveyors have a solid shaft that goes through the flighting of the screw. The shaft holds the flighting off the bottom of the trough. Benefits of this conveyor are that they can be of longer length, there is no need for a liner and the associated maintenance, and they can run at higher RPMs since there is no concern about liner wear. The traditional screw conveyor is generally considered low maintenance.

Shaftless Screw Conveyors

Shaftless Screw Conveyors’ simple, pipeless design employs fewer parts than conventional shafted-screw conveyors, reducing lifetime maintenance costs. It enables higher trough loading and lower RPMs, maximizing the volume of materials conveyed. Shaftless Screw Conveyors eliminates jamming and buildup typical in shafted-screw conveyors for greater uptime, higher efficiency, and lower maintenance. By eliminating hanger and end bearings to reduce maintenance and increase efficiency, the shaftless conveyor enables direct transfer to another conveyor.

Advantages

Shafted

- Ideal for conveying dry to semi-fluid bulk materials – free flowing to sluggish

- Cost-effective when compared to other conveying devices such as belt conveyors

- Efficiently distributes bulk materials to various locations using multiple inlet and discharge points

- Totally enclosed for dusty, corrosive or hazardous environments

Shaftless

- Ideal for handling sticky and sluggish bulk materials

- Improved conveying efficiency when compared to other types of conveyors

- Internal bearings are eliminated

- No hanger bearing supports

- No center pipe that causes product build up

- Full product clean out

- Replaceable trough liner

- High wear properties