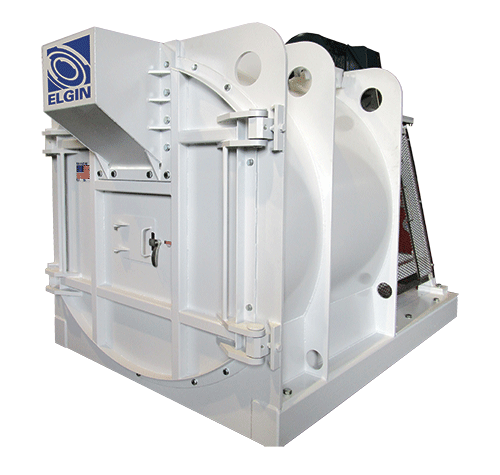

CMI Chip Wringer

Chip Wringer Overview

The CMI-8200™ Chip Wringer is used to dry metal chips in order to recover valuable coolant, and increase scrap value. Depending on the material and cutting fluid, dryness to less than 2% residual can be achieved in your chip recovery operation.

Featuring a patented bowl liner design that evenly distributes chips on the screen resulting in uniform moisture removal throughout the entire bed of chips. This design also creates substantially reduced vibration and downtime normally due to unbalanced chip loads. In addition, equal screen wear throughout its circumference by utilizing fixed liner acceleration vanes that never need adjustment.

When the wringer is coasting to stop position, ‘G-Force’ decreases until the chip weight overcomes the centrifugal force. When this point is reached, the dry chips automatically discharge into the conveyor system. The result is considerably less wear and tear which can be caused by severe vibration due to unbalanced loads at start-up with vertically designed units.

Chip Wringer Features

Hinged door, with two bolt release or quick release latches, facilitates easy access and inspection.

Motor is externally mounted with standard V-belt drive components also accessible from the outside of the unit.

Stainless steel bowl liner allows for even chip distribution resulting in even screen wear without adjustments.