BlueWave™ Composite Shaker Screens

BlueWave™ Screen Overview

Elgin’s BlueWave™ Composite Shaker Screens optimize solids control efficiency to reduce costs and waste volumes, regardless of the targeted formations and drilling applications.

Performance

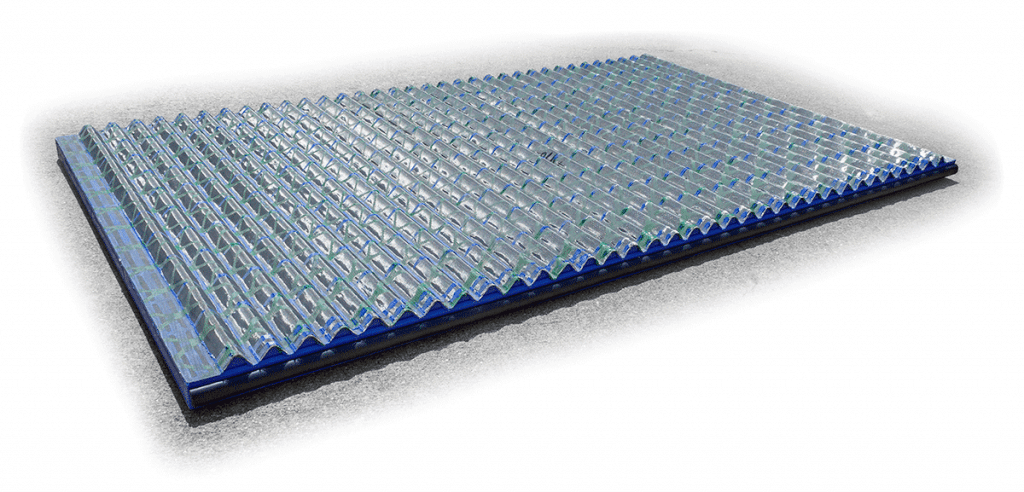

Elgin®’s newest pre-tensioned, BlueWave composite screen provides for 47% more surface area than a standard flat-panel pre-tensioned flat-panel screen. This additional surface area directly translates into a higher hydraulic capacity. This means that higher flow rates with more viscous drilling fluids can be managed.

Quality

Composite screens inherently have a higher quality control. There is no chance for discontinuities and/or variations in the quality. There is no chance for human error in the welding, powder-coating, and/or grinding process. This ensures consistent quality with each screen used.

BlueWave™ Screen Features

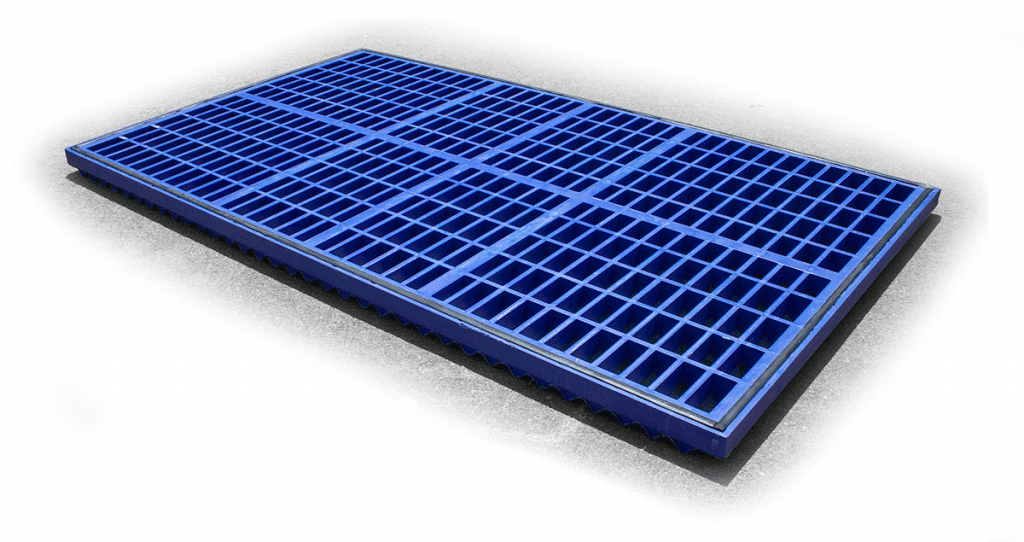

Resists Premature Delamination – Metal framed screens are made from components that are laminated together by powder-coat paint. This bond is based on the consistency of the powder-coat, how well the metal frame was cleaned, and how well the heat press temperatures were controlled. BlueWave™ composite screens are not laminated. As such, there is no ability for the perforated plate or the wire mesh to prematurely separate from the frame.

Composite Polyurethane Technology – traditional screens are constructed using a rigid steel frame and perforated plate; in which layers of woven wire cloth are bonded with powder-coating. New manufacturing technology has advanced shaker screen construction using composite material with steel reinforcement. These changes increase strength, longevity, and performance.

Improved Handing – Composite screens have less sharp edges that can cut operators when handled. Molded products provide for a cleaner edge and minimize the number of sharp burrs and edges.