Decanter Centrifuge Repair Services

Elgin has vast experience in the service and refurbishment of the industry’s most popular centrifuges. Elgin can provide a one-stop-shop service relative to maintaining your entire centrifuge fleet. Instead of distributing your maintenance service amongst a variety of supplier, Elgin provides a single point of contact.

Though Elgin’s field service, repair and remanufacturing services are tough to beat, our greatest value is in the depth of engineered spare parts offered. Spare parts provided by Elgin are designed to outperform those typically available from aftermarket suppliers. This is not simply because of our commitment to dimensional accuracy, but because of the enhanced features that we commonly incorporate improve the performance of your centrifuge.

Elgin can fully service and repair the following centrifuges for the Oil & Gas industry:

- Alpha Laval Lynx 20 & 40™

- NOV HS-3400™

- Hutchinson & Hayes 1448™

- Tecumseh 1655 & 1655 FVS™

- G-Tech 1656™

- Tomoe TDM-50™

- Derrick DE-1000 & DE-7200™

Elgin can fully service and repair the following centrifuges for the Rendering industry:

- Bird™

- Flotweg™

- Sharples™

- Centex™

- FLSmidth™

Elgin’s centrifuge repair services team will fully inspect the centrifuge upon receiving. A detailed inspection report is generated, detailing repair/replacement recommendations with complete cost analysis for customer review. Centrifuge repair services typically include:

- Disassembly of rotating assembly for complete cleaning, replace damaged or worn tiles on scroll, replace solids end discharge plows & liners, pillow block or conveyor belt replacement

- Gearbox cleaning & rebuild

- Top & Bottom interior covers cleaning

- Rebalancing of complete rotating assembly

- Repair/Repainting of base or skid structure

- Control panel/electrical cable inspection & repair

Custom Control Systems

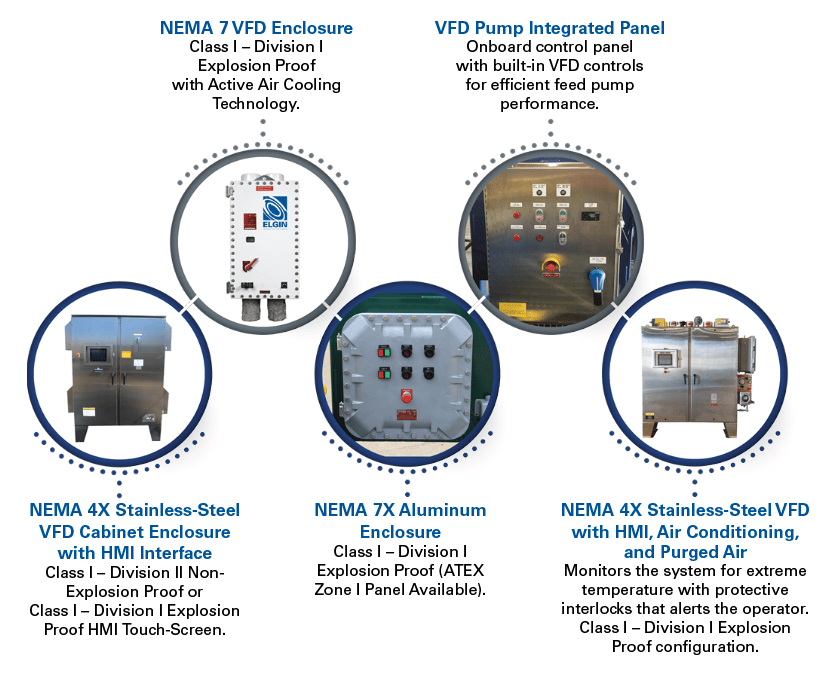

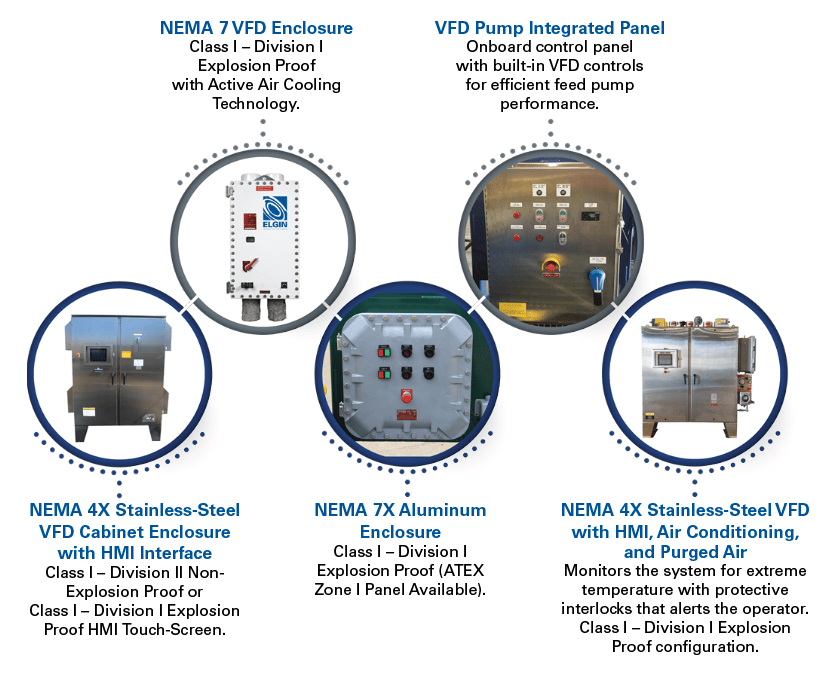

Elgin can provide full control system support for your decanter centrifuge. If you are in the need of a new control system or simply wish to achieve enhanced performance and monitoring capabilities, Elgin can supply you with a variety of control system options, including NEMA 7X Explosion Proof control systems, NEMA 4X Non-Explosion Proof control systems, and NEMA 7X Explosion Proof control systems with Nitrogen Purging. Depending on your needs and the ultimate application, we can develop a control panel that fits your needs and your budget.

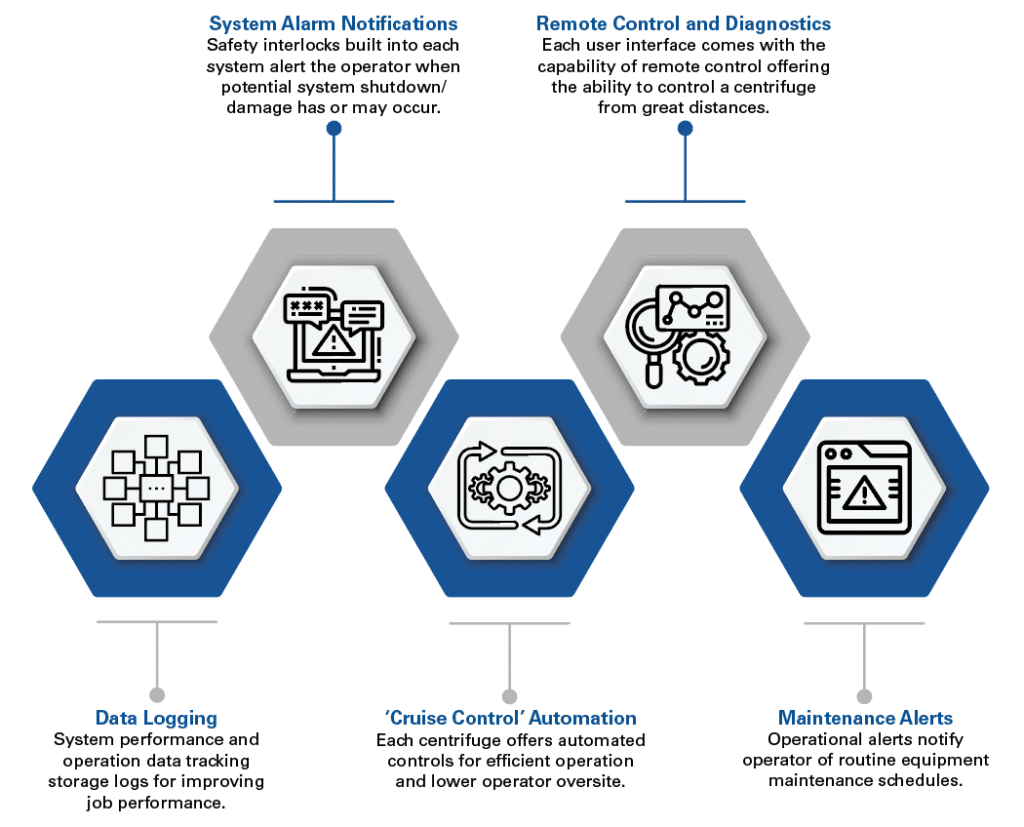

Proprietary System Automation

Elgin’s proprietary user interface provides complete control of all systems, as well as, a sophisticated set of diagnostic tools, information libraries and fault logs. Control systems include a variety of enhanced features including, internal lighting, ventilation and heating, Ethernet porting for diagnostics and programming updates, and a custom designed user interface that allows for maximum operating flexibility and control.

Panel upgrades can include onboard Wi-Fi network module allowing for remote operation/monitoring via laptop, tablet or smart phone.