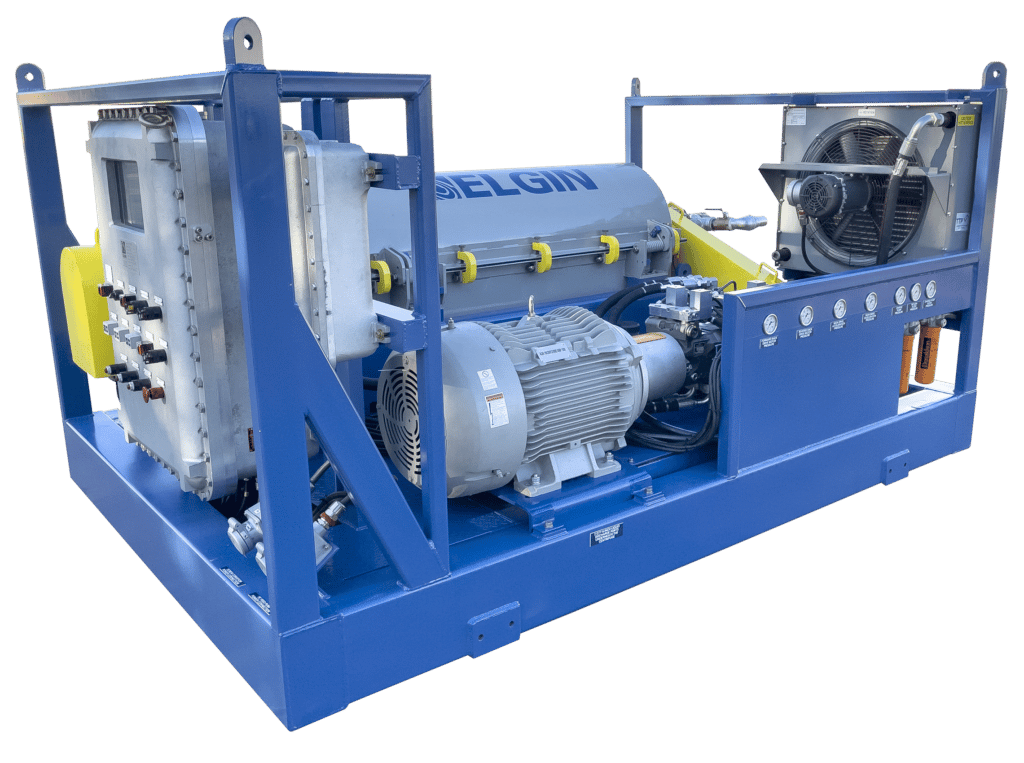

Apex 16VFD™ Decanter Centrifuge

Apex 16FHD™ Centrifuge

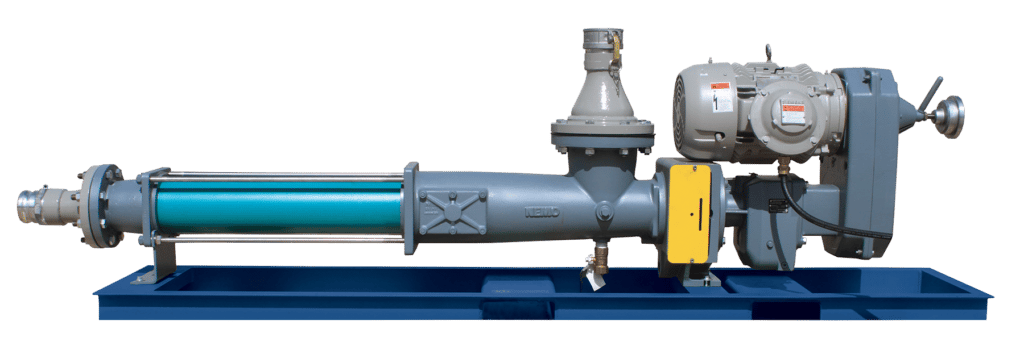

Apex 16VFD™ Slimline Centrifuge

Apex 16VFD™ Overview

Whether you are working toward maximizing barite recovery or looking to get the most out of your “zero-discharge” closed-loop system, Elgin’s field proven decanter centrifuges are a perfect choice. With over 500 units installed worldwide, Elgin introduces its newest member to its line-up of high-quality, oilfield engineered centrifuges, the Apex 16VFD™ Decanter Centrifuge.

Power and Performance

Elgin’s Apex 16VFD™ is fitted with a NEMA premium, continuous duty, energy-efficient, poly-chain driven, 60 hp main drive and a direct-coupled 20 hp back-drive. All Apex 16VFD™ explosion proof motors used by Elgin are suitable for applications requiring UL or CSA certification for hazardous locations. The 60 hp main drive can operate the centrifuge up to a maximum rotational speed of 3,400 rpm, therefore generating more than 2,300 G’s of force. Using an inclined motor mount, motor and belt maintenance is made easy by the adjustment of two jack screws. No additional motor mounts, brackets or tensioning devices are required.

Apex 16VFD™ Features

- Optional 20 HP back drive module for full variable frequency drive performance.

- Six (6) stainless-steel, epicentric, liquid-end discharge ports.

- Four (4) wide-mouthed, tungsten carbide discharge ports and plows.

- Built in safety interlocks protects the centrifuge from damage.

Available in various length configurations, screw conveyors offer high-performance in moving discharged solids over great lengths.