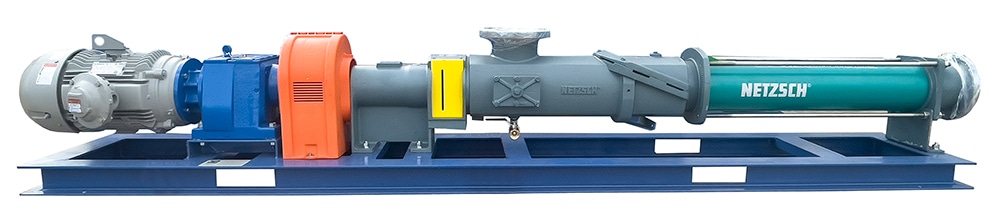

Progressive Cavity Feed Pumps

KTPC-NM063-P101 Progressive Cavity Pump

KTPC-NM090-P101 Progressive Cavity Pump

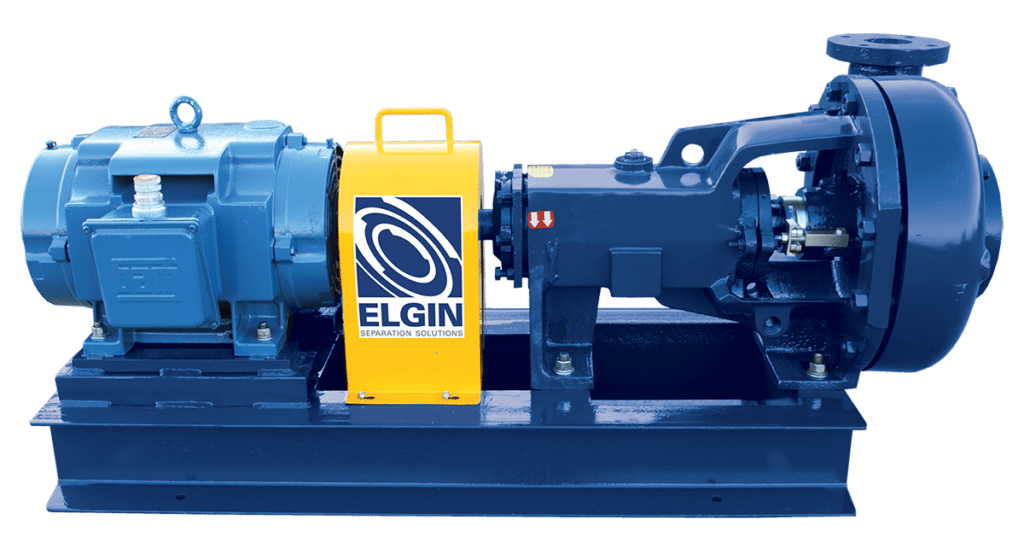

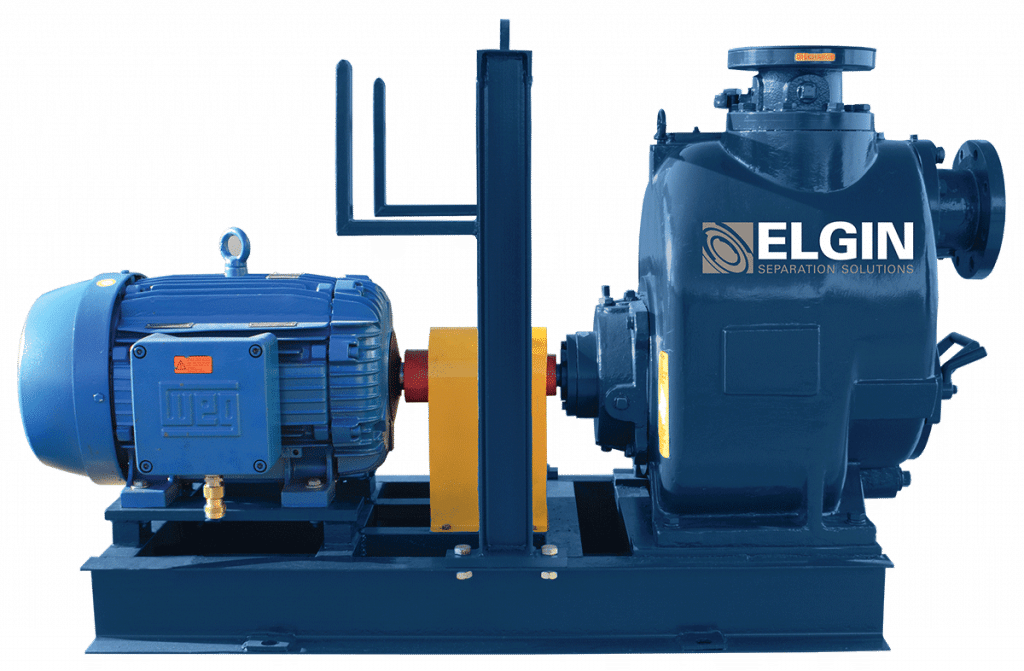

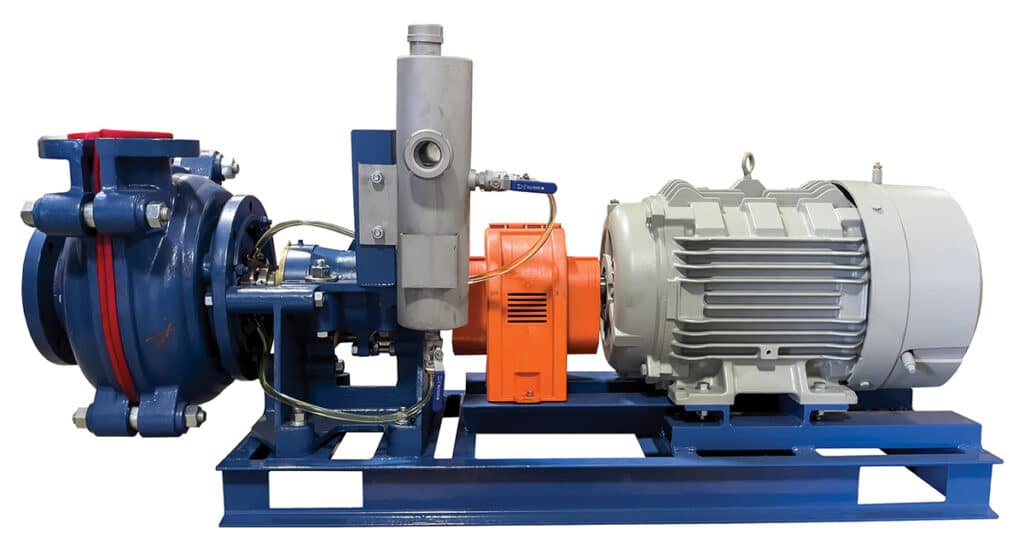

Progressive Cavity Pump Overview

To ensure a well-balanced feed, with consistent feed pressure, Elgin can supply a variety of custom-configured progressive-cavity feed pumps (“PC pumps”). PC pumps can improve the centrifuge performance, extend the life of a centrifuge, and reduce overall operations and maintenance costs when properly operated.

Elgin PC pump packages can be supplied in a variety of skid configurations (i.e. wide field skid and narrow plant skid), as a mechanically-variable gearbox or a direct gearbox with inverter-duty, VFD-driven motor, and a variety of motor installation configurations (i.e. in-line, offset, and “piggy-back”).

Elgin’s PC pumps are mated with a premium gearbox and premium, continuous duty, energy-efficient, explosion-proof motor (non-explosion proof motors are for applications requiring UL or CSA certification for hazardous locations.

Pump Features

Improved Maintenance

Full drive train, including stator, rotor, rod, and seal can be removed in minutes without electrically disconnecting the pump. Maintenance can be conducted in a matter of minutes, instead of hours.

Constant Parameters

Continuous low-pulsation conveyance unaffected by fluctuations in pressure and viscosity.

Extended Life

Due to the low running speeds of the pump, there is a significant reduction in equipment wear.

Easy to Service

No special tools are required, as the pump can be serviced with only a wrench and an allen key.

Split Coupling

The split coupling body provides a quick and easy way to disassemble and maintain the pump.