Tabor Horizontal Vibrating Screen

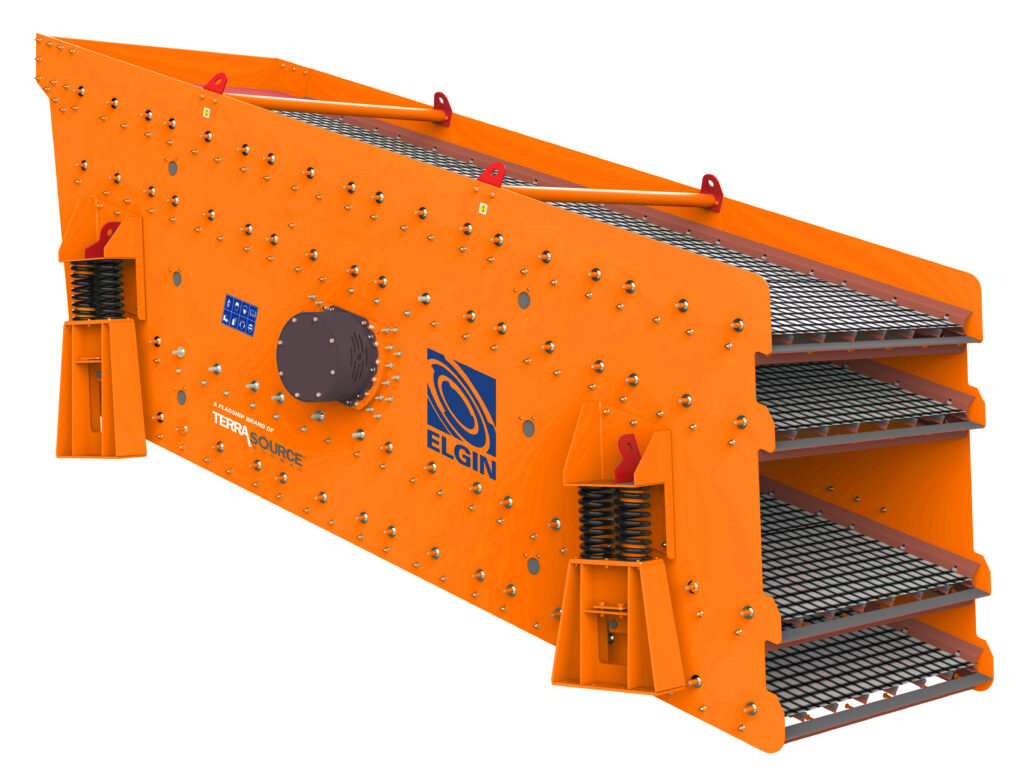

The Tabor™ Horizontal Vibrating Screen by Elgin is a trusted solution for high-volume material sizing, dewatering, and rinse applications in mining and aggregate operations. Known for its rugged construction and efficient linear motion drive, it has been delivering reliable, trouble-free performance since 1961.

Designed to excel in space-limited, high-production environments, the Tabor™ Horizontal Screen offers customizable configurations, a wide range of screen media options, and advanced features like the QuickChange Spring Seat System—making it an ideal fit for coal, aggregates, and industrial minerals processing.

Tabor™ Horizontal Vibrating Screen Overview

A high-performance screening solution built for durability, efficiency, and versatility in demanding mining and aggregate environments. With a legacy dating back to 1961, Tabor screens have become industry standards for material sizing, drain-and-rinse, and dewatering applications. Its linear-motion TH drive ensures smooth, consistent operation for high-volume material handling.

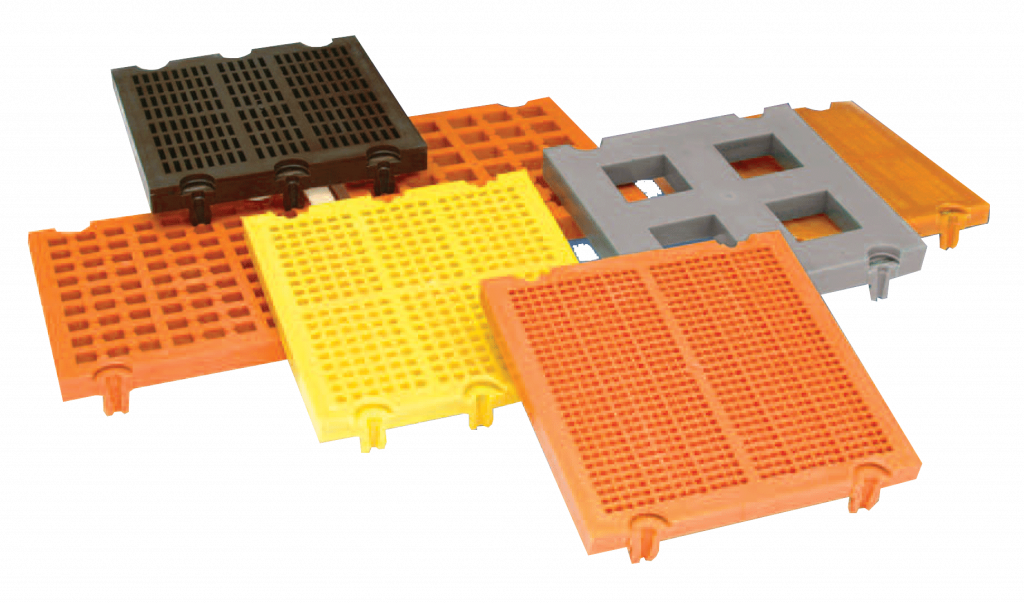

Engineered with heavy-duty A36 steel side plates, huck-bolted assembly, and reinforced deck support frames, the Tabor screen is built to last in tough conditions. It accommodates a wide variety of screen media, including woven wire, polyurethane, rubber, and perforated plates, allowing for full customization to meet specific operational needs. Available in single, double, and triple deck configurations, it fits operations with both space constraints and high throughput demands.

Notable features include the QuickChange Removable Spring Seat System, which reduces downtime by simplifying maintenance, and adjustable vibration settings that optimize performance across material types. Optional upgrades like lined feed boxes, dust enclosures, and remote drive bearing monitoring further enhance functionality and ease of use. With sizes ranging from 3′ to 8′ wide and up to 24′ long, the Tabor™ Horizontal Vibrating Screen is a reliable, customizable solution for coal, aggregates, potash, and more.

Features and Benefits

- Linear-motion TH Drive

- Huck-bolted assembly on all majorbody components

- Steel coils for floor mounting

- Heavy-duty steel side plates with vertical and longitudinal reinforcing bars

- Rugged deck support frame with cross tube members and side channels

- Interchangeable screen media

- QuickChange Spring Seat system

- A variety of paint options for maximum corrosion resistance

Custom Options

- Lined feed boxes

- Pivoting motor bases

- Dust enclosures

- Choice of solid decking or independent cross members

- Patented QuickChange Removable Spring Seat System

- Polyurethane-dipped drive bottoms

- Remote drive bearing monitoring