SUBMERGED INTAKES

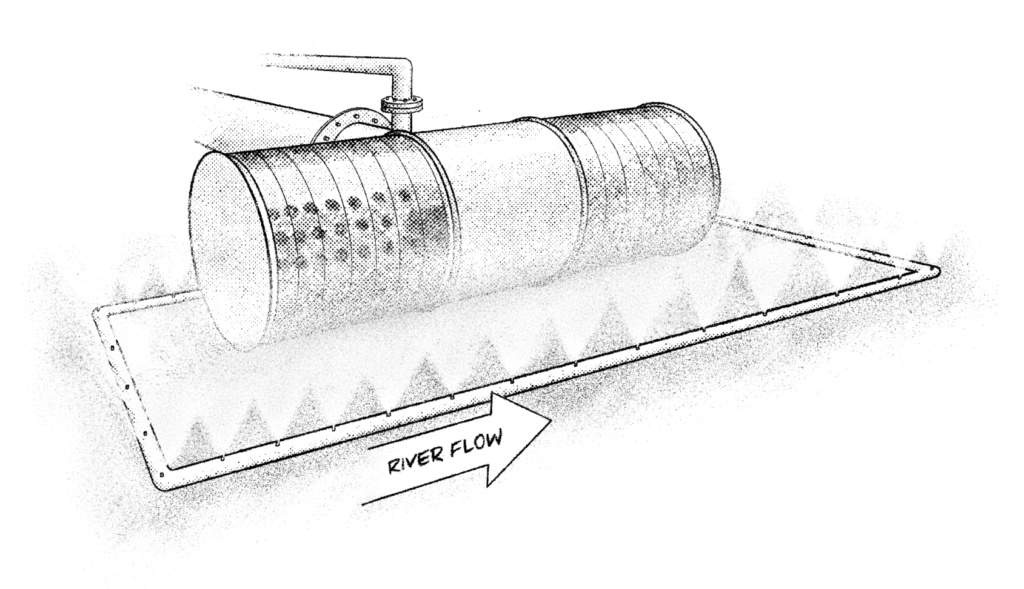

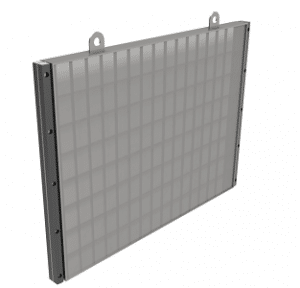

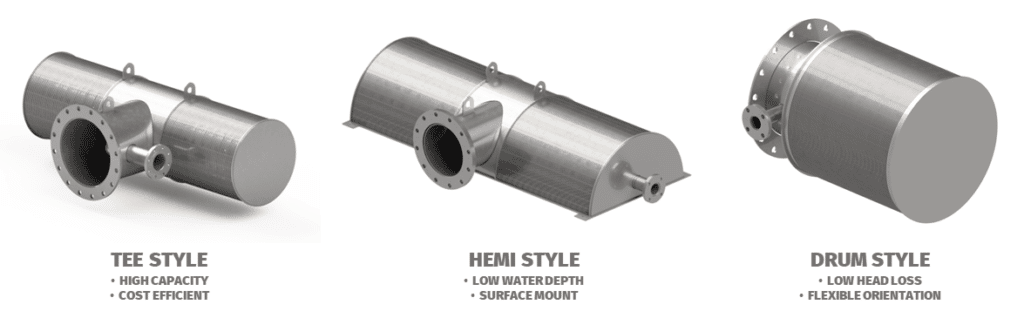

Submerged cylindrical screens are popular for large intake capacities. Elgin’s offerings are considered “passive,” meaning they do not have moving parts under water. The screen elements in the water source use screen area to spread out the suction from the pumps, thereby minimizing clogging and impact to the surrounding environment.

The most common arrangement is a cylindrical screen with a compressed air cleaning system (AirBurst). When compressed air systems are not feasbile, an oversized screen can minimize clogging. Elgin offers a variety of cylindrical screen arrangements to meet your needs.

Resources

Case Studies / Videos

Next Steps

SCREEN CLEANING SYSTEMS

We believe the basis for an effective cleaning system is reliability and simplicity. Common components make maintenance a breeze and stationary parts eliminate the need for complex retrieval systems.

AIRBURST SYSTEMS

Delivers a burst of compressed air to remove debris from the surface of the screen. The system includes control schemes that can be fully automatic or manual. See our standard packages for more detail.

Our PLC-based controls can stand alone or be fully integrated into the local control system (SCADA). An intuitive user interface and large HMI touchscreen will guarantee a smooth handoff to the end user.