Composite Shaker Screens

Composite shaker screens inherently have a higher quality control. There is no chance for discontinuities and/or variations in the quality. There is no chance for human error in the welding, powder-coating, and/or grinding process. This ensures consistent quality with each screen used. Composite screens provide for higher tension of woven wire cloth. As such, they provide for an improved cut point and extended wear life. Composite shaker screens optimize solids control efficiency to reduce costs and waste volumes, regardless of the targeted formations and drilling applications. Elgin’s composite screens fully comply with API 13C standards and have been tested by an independent third-party company.

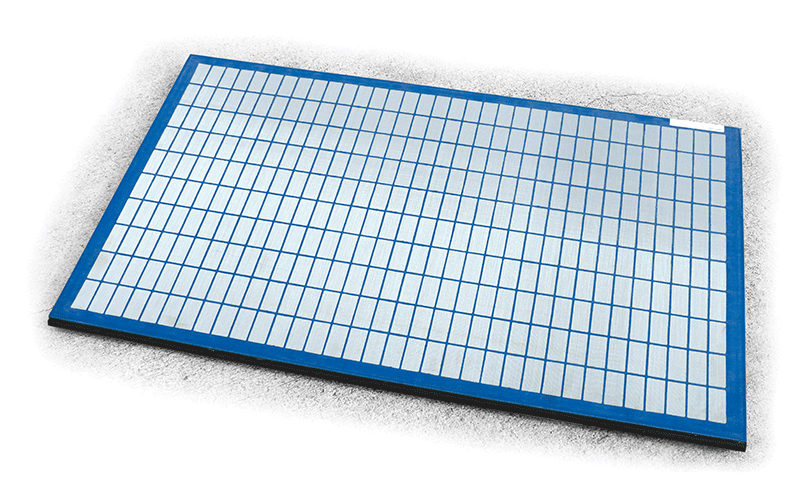

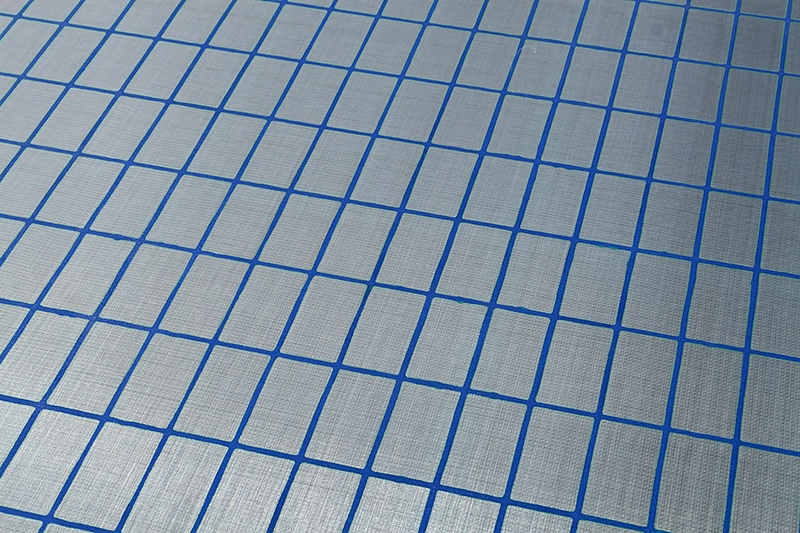

BlueCrest Composite™ Screens

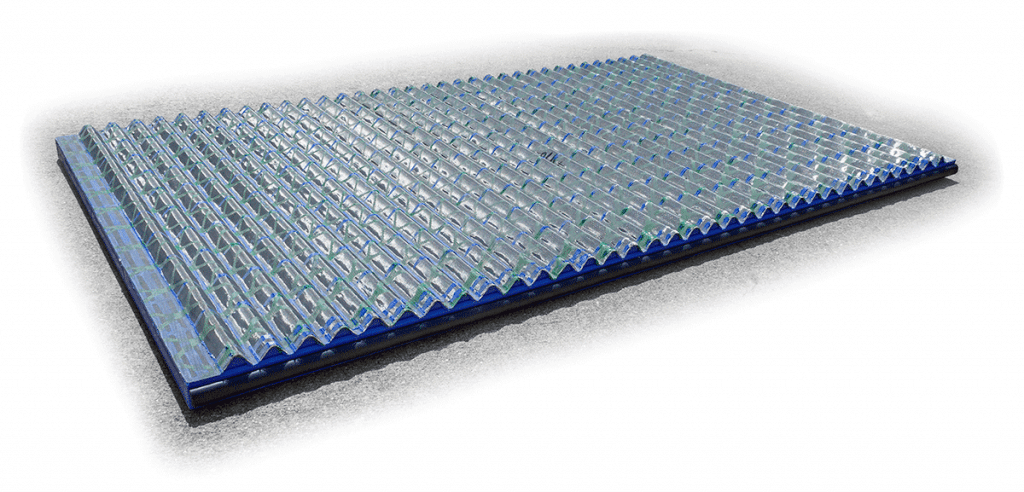

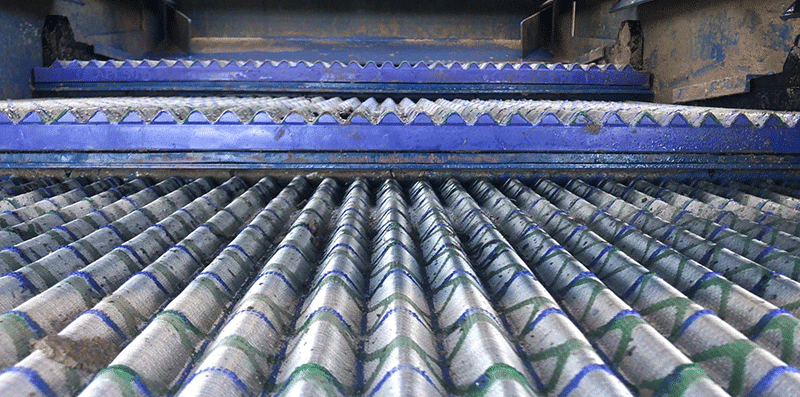

BlueWave Composite™ Screens

Composite screens provide for higher tension of woven wire cloth. As such, they provide for an improved cut point and extended wear life. Nitrile perimeter gasket provides hydrocarbon resistance and mitigates solids bypass.

Woven Wire Cloth

Nitrile Perimeter Gasket

Composite Screens Overview

Composite Screen Technology – traditional screens are constructed using a rigid steel frame and perforated plate; in which layers of woven wire cloth are bonded with powder-coating. New manufacturing technology has advanced shaker screen construction using composite material with steel reinforcement. These changes increase strength, longevity, and performance.

Performance – Elgin’s Composite screens provide higher surface tension. The heating process causes the wire mesh to contract and provide for a tighter surface tension. The higher the surface tension, the longer lasting the screen. This means that higher flow rates with more viscous drilling fluids can be managed. Elgin’s wave-profile screen provides for

Quality – Composite screens inherently have a higher quality control. There is no chance for discontinuities and/or variations in the quality. There is no chance for human error in the welding, powder-coating, and/or grinding process. This ensures consistent quality with each screen used.

Composite Screen Benefits

Resists Premature Delamination – Metal framed screens are made from components that are laminated together by powder-coat paint. This bond is based on the consistency of the powder-coat, how well the metal frame was cleaned, and how well the heat press temperatures were controlled. Composite screens are not laminated. As such, there is no ability for the perforated plate or the wire mesh to prematurely separate from the frame.

Increased Surface Area – Elgin’s BlueWave Composite™ screen provides for 47% more surface area than a standard flat-panel pre-tensioned flat-panel screen. This additional surface area directly translates into a higher hydraulic capacity. This means that higher flow rates with more viscous drilling fluids can be managed.

Storage Life – The storage life of a metal framed screen presents a number of complications. Shipping of the screens, or mishandling of them, can cause the screens to warp. The base metal, despite the application of powder coat, can result in corrosion. This is not the case when managing composite screens. Screen frames do not dent or warp from mishandling. They also have no exposed metal, so there is no chance for frame corrosion.