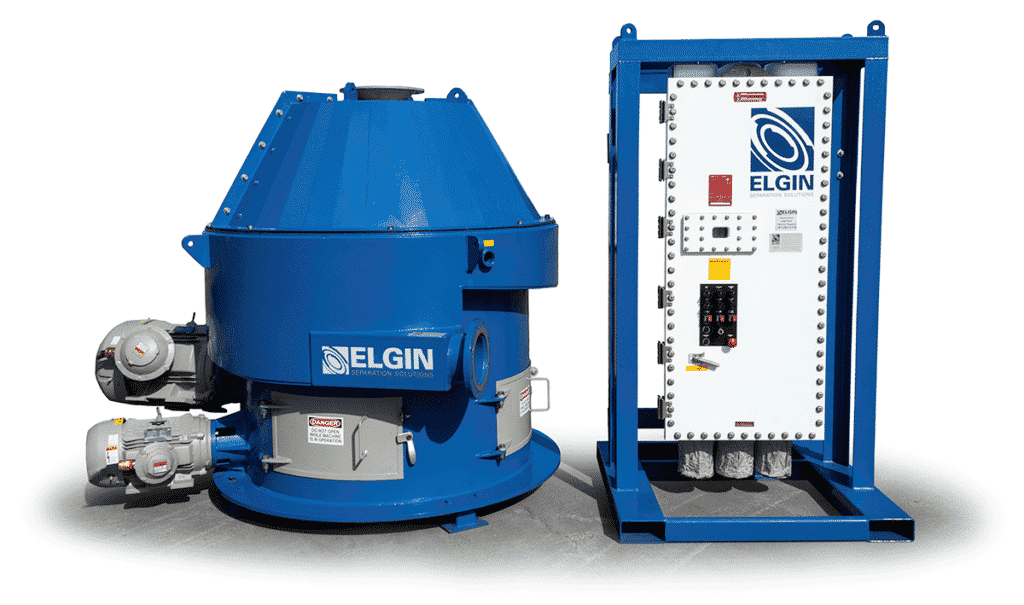

CSI-04™ Vertical Cuttings Dryer

Elgin’s CSI-04™ Vertical Cuttings Dryer has been the industry’s most recognized & reputable VCD available in the market. No other brand has achieved more success or recovered more drilling fluid, than the CSI-04™ VCD. There have been more than 850 CSI™ vertical cuttings dryers delivered to the market.

Every major solids control & waste management service provider in the market operate CSI™ dryers (including, but not limited to Baker Hughes™, Halliburton™, M-I Swaco™, Weatherford™, Ava / New Park™ and NOV™*).

CSI-04™ VCD Operation

CSI-04™ Overview

A properly deployed CSI-04™ Vertical Cuttings Dryer, can significantly reduce waste disposal costs, dramatically lower whole mud loses within those wastes, and improve the overall quality of the drilling fluid by allowing the shale shakers and centrifuges to be used at their full operating potential.

Designed to reduce oil on cuttings by up to 85%, The CSI-04™ VCD is the perfect solution for processing up to 40 tons per hour.

VCD applications are driven by three key objectives:

- Drilling Fluid Reclamation

- Waste Solid Reduction

- Waste Solid Declassification

Elgin CSI-04™ VCD incorporates several unique features, including ceramically-lined inner housing, internally mounted launder section spray bar, automatic shut-off systems, multiple access/maintenance doors, and individually balanced rotating components to ensure vibration-free operation.

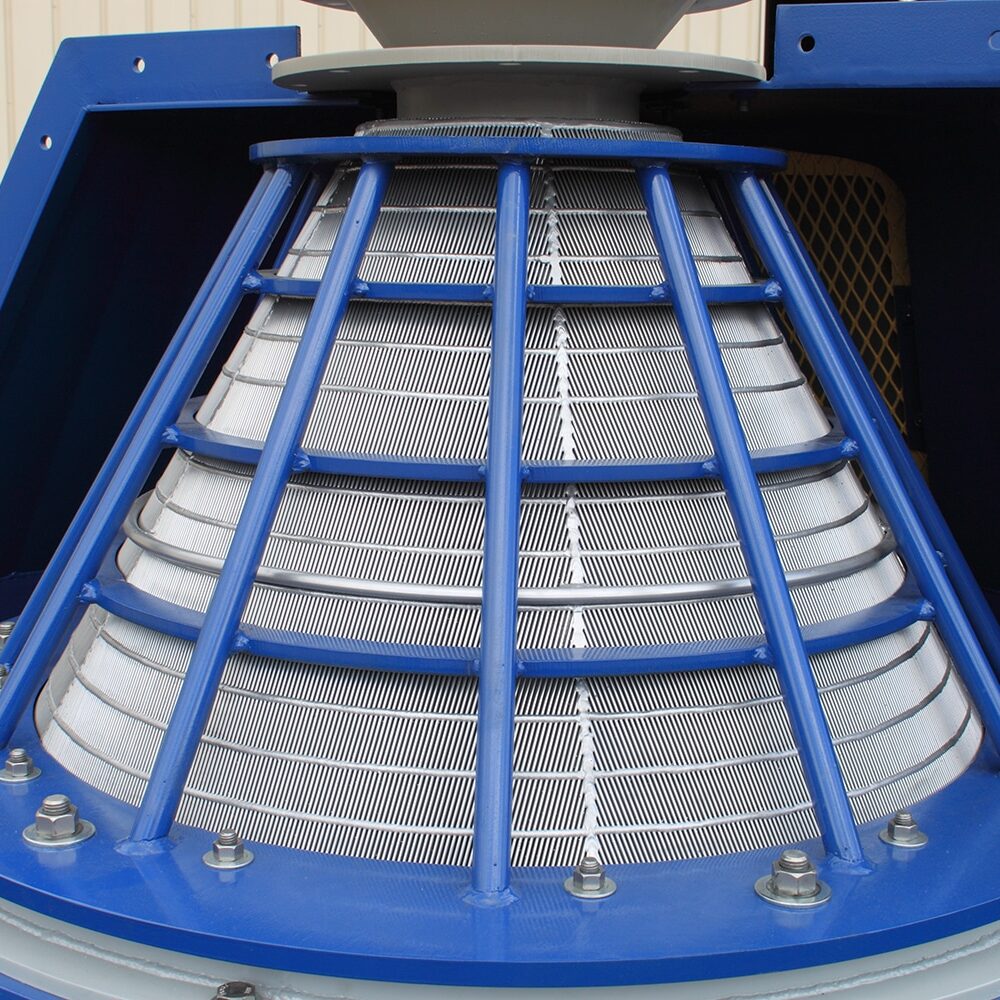

Most importantly, Elgin manufactures its own host of screens and flite assemblies, further ensuring that operators have the right system for the right operating conditions.

CSI-04™ Features and Benefits

Engineered Flites

Various blade materials and

coatings available

(Tungsten, Ceramic, & Hard Chromed)

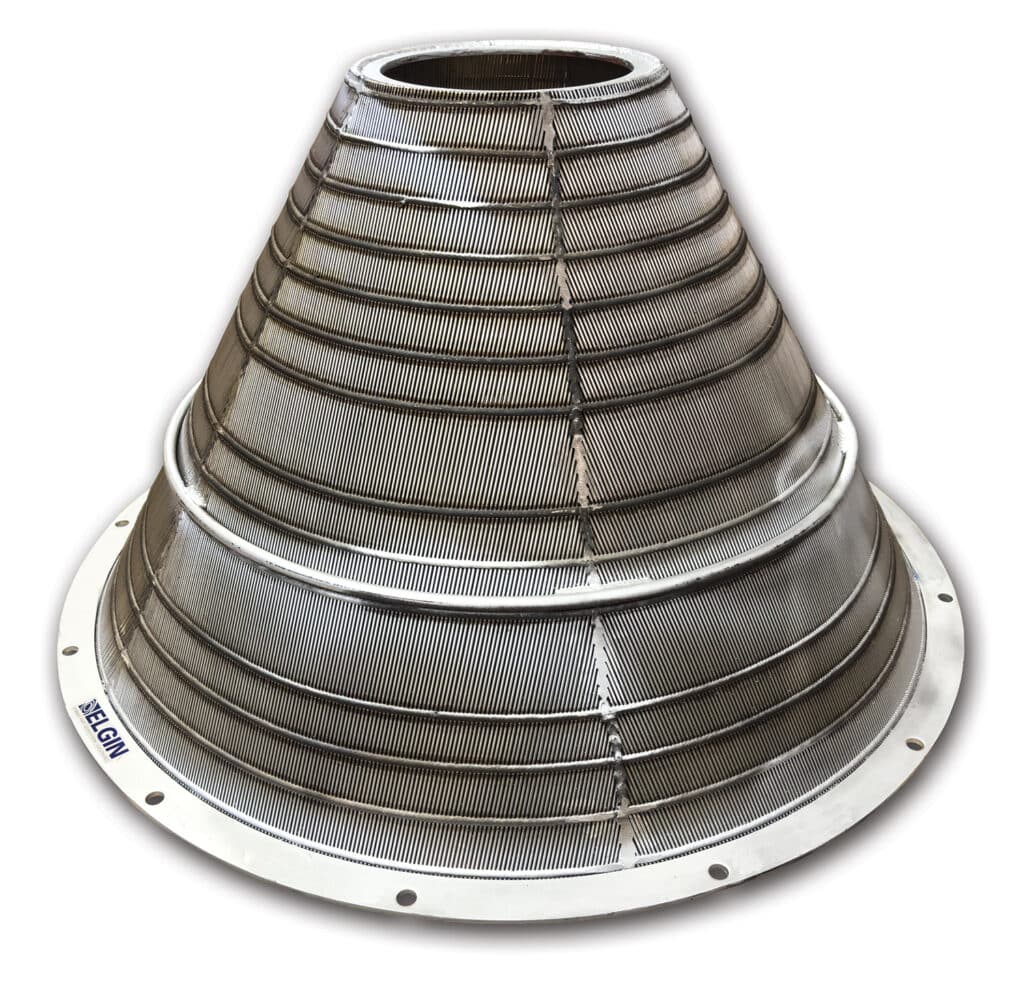

Screen Design

Fully TIG welded and chromed screens can help customers extend screen

life as long as a year

Spray Bar

Integrated spray bar into the launder section ensures VCD can withstand longer operating periods between service

Access Hatch

Three hatches located around the body for cleaning of the solids discharge section and maintenance

VCD Resources

- CSI Cyclone™ VCD Product Brochure

- CSI-04 Oil-Sealed Gearbox Retrofit

- VCD Product Presentation

- VCD Screen and Flite Selection Guide

- VCD Safety Hazards White Paper

- VCD Application in Solids Control Program

- CSI-D4 Deployment Case Study

- CSI-D4 Package System Video

- Vertical Cuttings Dryer Article

- Request A Quote

Elgin’s CSI-D4™ Vertical Cuttings Dryer is the most sophisticated VCD on the market today. Capable of processing oil-based and water-based waste material with no need for conversion.