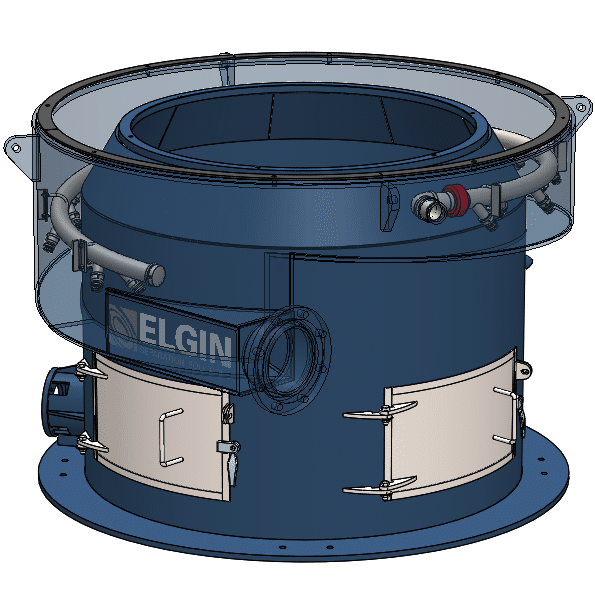

CSI-E4 Cyclone™ Vertical Cuttings Dryer

CSI-E4 Cyclone™ Overview

Elgin’s CSI Cyclone™ E-Series Vertical Cuttings Dryers are the next evolution of the industry leading CSI-04™and CSI-03™ VCD’s. The new CSI-E4 Cyclone™ Vertical Cuttings Dryer is designed with an improved oil-sealed gearbox drive unit that requires no active lubrication system for operation. More importantly, the new gearbox design provides for improved dryer performance when compared to their predecessors. Elgin’s CSI Cyclone™ E-Series eliminates active system lubrication components while increasing G-force and speed performance.

CSI-E4 Cyclone™ Features and Benefits

Engineered Flites

Various blade materials and coatings available

(Tungsten, Ceramic,

& Hard Chromed)

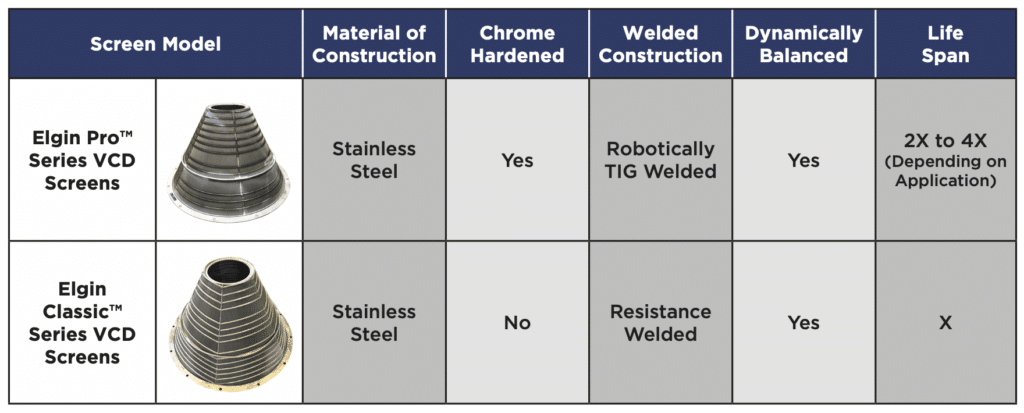

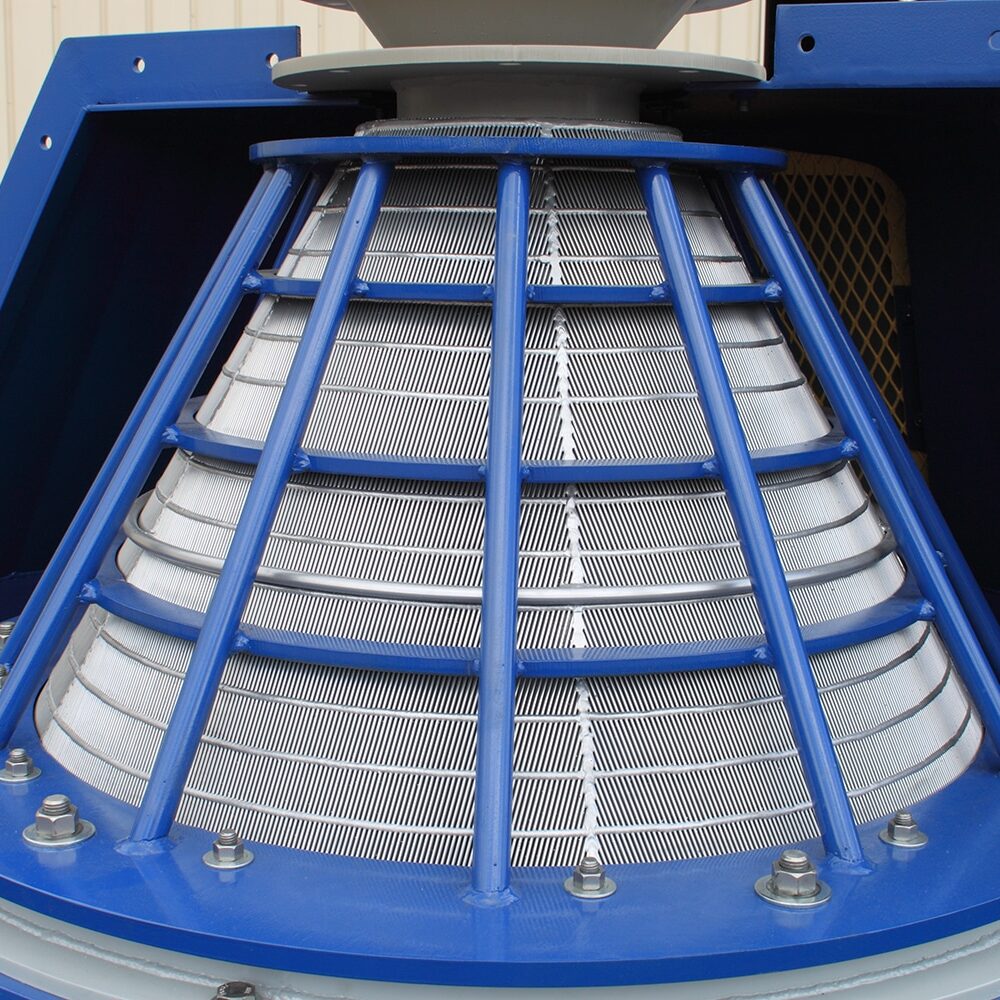

Screen Design

Fully TIG welded and chromed screens can help customers extend screen life as long as a year

Spray Bar

Integrated spray bar into the launder section ensures VCD can withstand longer operating periods between service

Conical Launder

Cork-screw launder design made to significantly lower the risk of a back-up within the VCD

Access Hatch

Three hatches located around the body for cleaning of the solids discharge section and maintenance