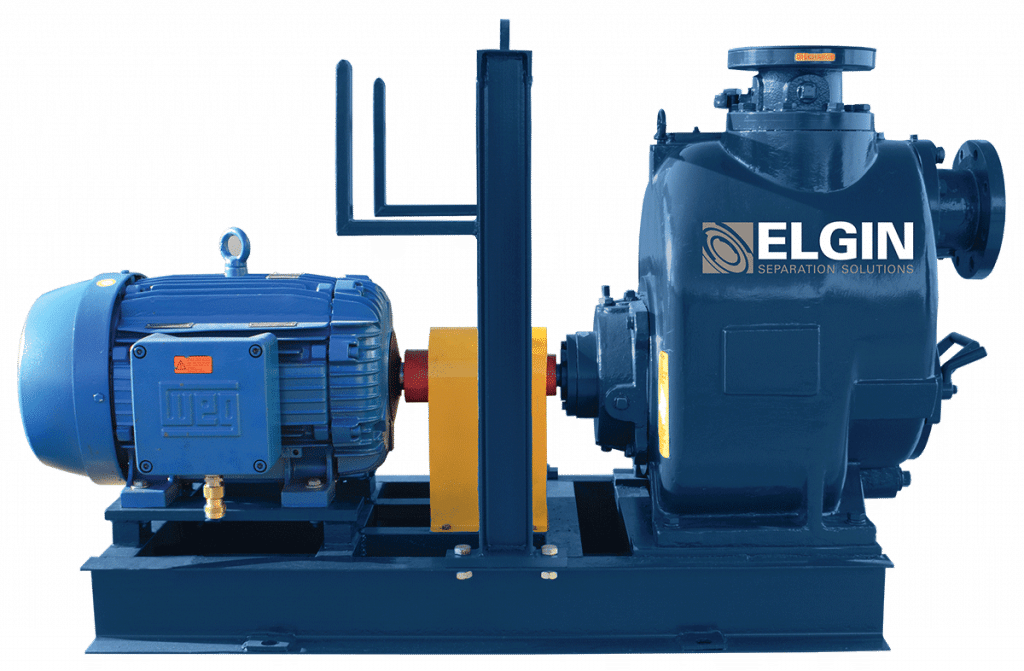

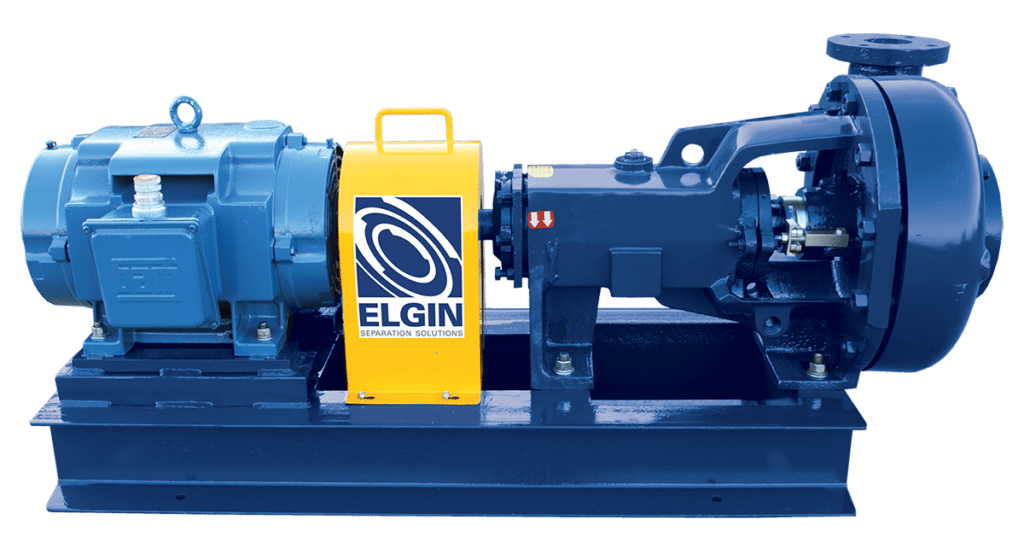

DuroLast RB/NE™ Abrasion Resistant Slurry Pump

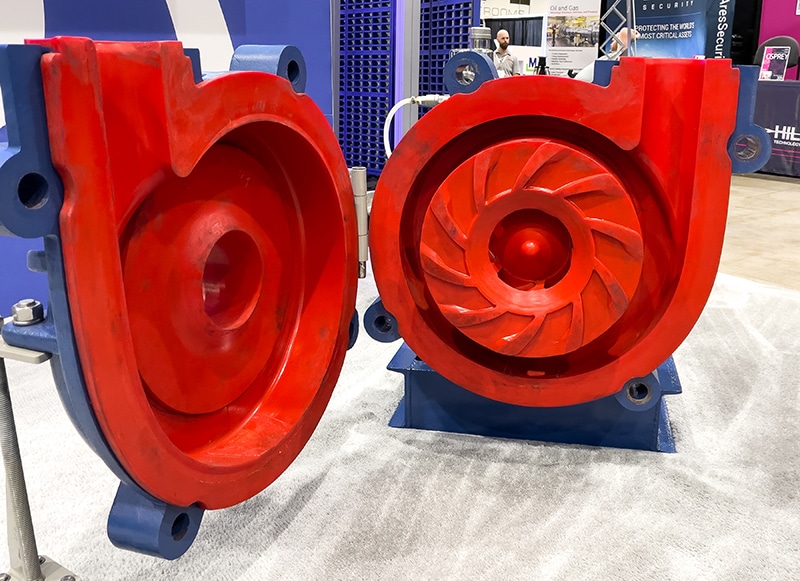

Abrasion Resistant Liner and Impeller Coating

Premium Heavy-Duty Mechanical Seal

Thermal Siphon Cooling Technology

DuroLast™ Pump Overview

Elgin’s DuroLast RB/NE™ abrasion resistant slurry pumps are designed to better manage abrasive materials associated with pumping operations. Whether operated as a standalone pump or part of Elgin’s turn-key solutions, abrasion resistant slurry pumps improve performance and extends pump life versus traditional pumps.

Abrasion Resistant Liner

Elgin’s DuroLast RB/NE™ pumps can be configured with either a HDPE Polyurethane or Nitrile liner that are designed to protect the casing from extended wear caused by abrasive and corrosive material while improving performance.

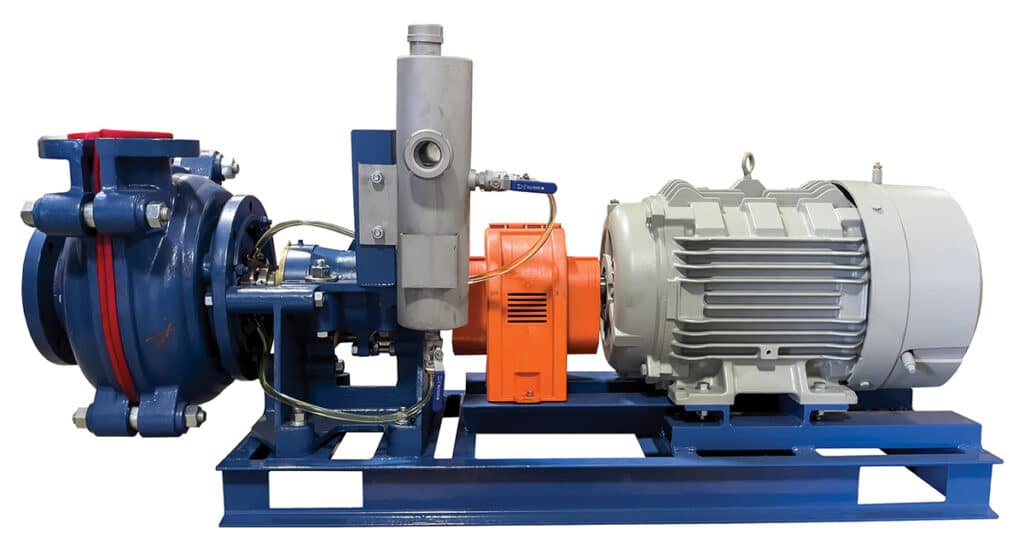

Premium Heavy-Duty Mechanical Seal

Pump performance is further enhanced with a premium heavy-duty mechanical seal that prevents leakage of fluid from the pump while improving performance when processing high temperature and highly corrosive material.

Thermal Siphon Cooling Technology

Diamond-core mechanical seal operation is further enhanced with onboard thermal siphon technology that prevents pump damage from run-dry operating conditions and lubricates components to prevent high temperatures from occurring.

Features and Benefits

- Two-part HDPE Polyurethane or Nitrile liner reduces casing wear from abrasive fluids. Polyurethane liner is designed for water-based applications while the Nitrile liner is for oil/chemical operations.

- Impeller wear is minimized with an elastomer coating.

- Access to pump bearings is made easy with a split casing design.

- Pump frames have been redesigned to reduce overall pump weight by 10%. Despite the weight reduction, the redesign has also improved pump strength to ensure long bearing life.

- Timken™ Quick-Flex coupling allows for ease of maintenance of the pump in the field.

- Multiple Applications – suitable for seawater, freshwater, drilling mud, as well as a host of industrial applications such as cement, mining dewatering, and many more.