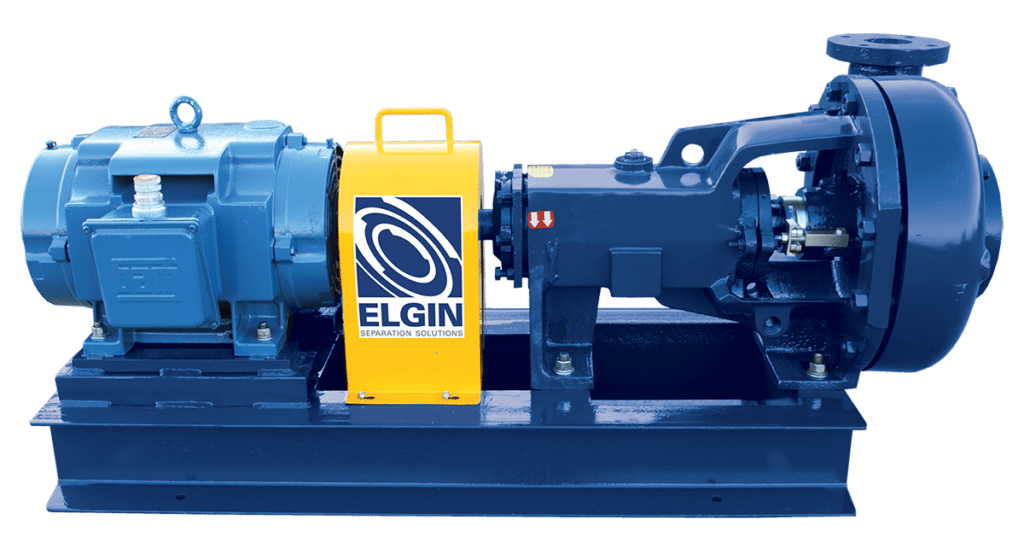

Self-Priming Pumps

Self-Priming Pump Overview

With over 25 years of experience in designing and manufacturing reliable solids control equipment for the oil & gas industry, Elgin recognizes the need for reliable and efficient self-priming pumps. Elgin’s line of self-priming, solids-handling pumps have been designed to reliably handle a myriad of solids-laden fluids with minimal maintenance.

Based on one of the industry’s most field-proven pump configurations, Elgin’s line of self-priming solids-handling pumps offer a trouble-free, non-clogging design. The large volute automatically reprimes in a fully open system, without the need for complicated suction or discharge plumbing.

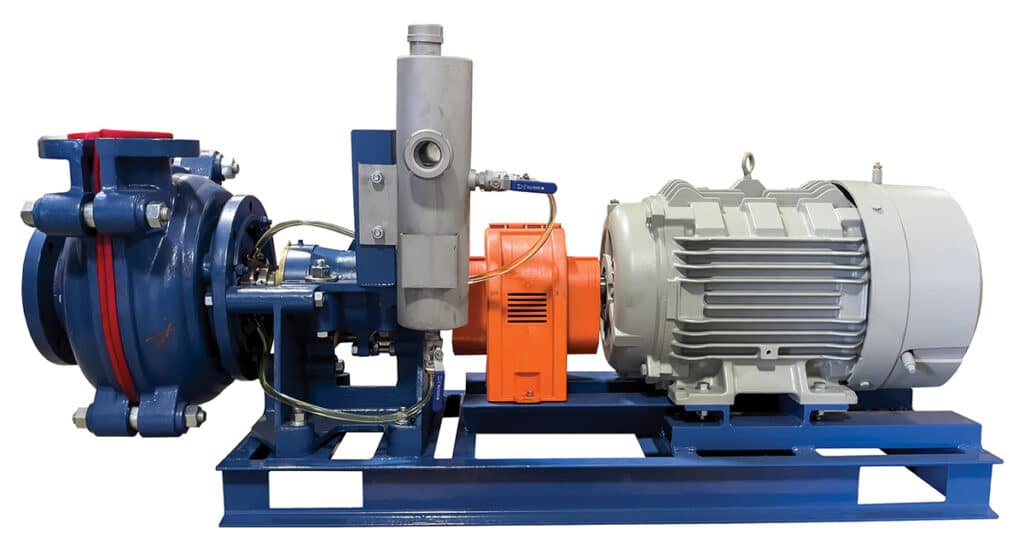

As a self-priming pump, the pump can be installed at heights above the solids-laden fluid being pumped. Service can be performed in-situ, without the use of special tools or disconnecting the suction or discharge plumbing. The dual-vane impeller, seal, wear plate, and flap valve can be easily accessed via the removable cover plate.

Pump Features

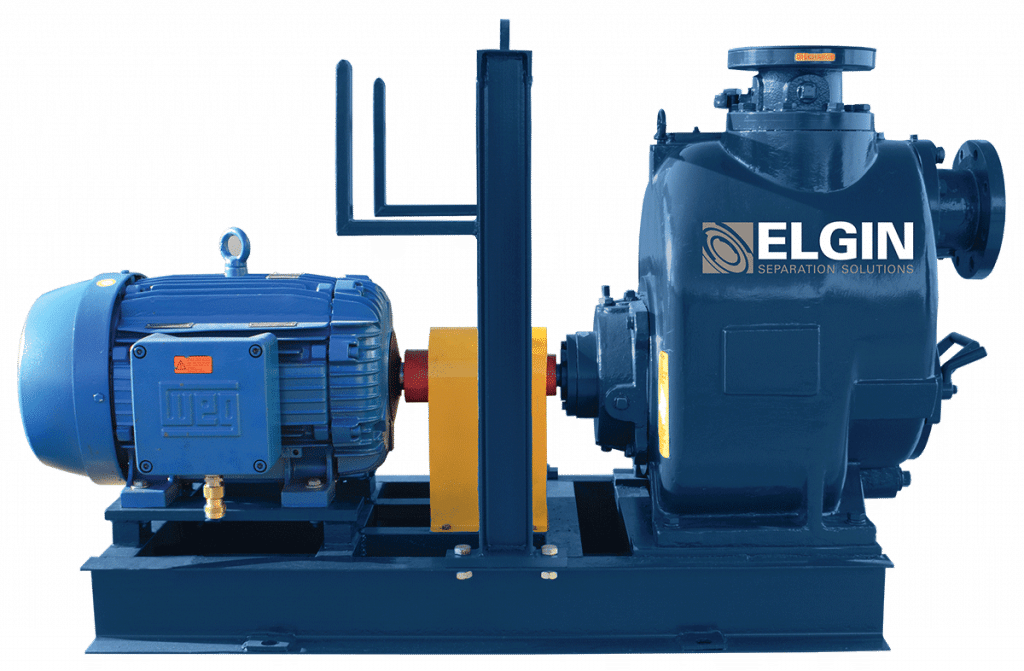

Solids Handling Impeller

Two-vane, semi-open, solids-handling impeller can handle solids up to 3’’ (76 mm) in diameter.

Mechanical Cartridge Seal

Oil-lubricated mechanical cartridge seal with stationary and rotating face of silicon carbide is designed for abrasive service.

Removable Rotating Assembly

As a single unit, the rotating assembly can be removed through the removable cover plate.

Easily Removed Cover Plate

Cover plate comes standard with two handles for quick and easy access to the pump interior.