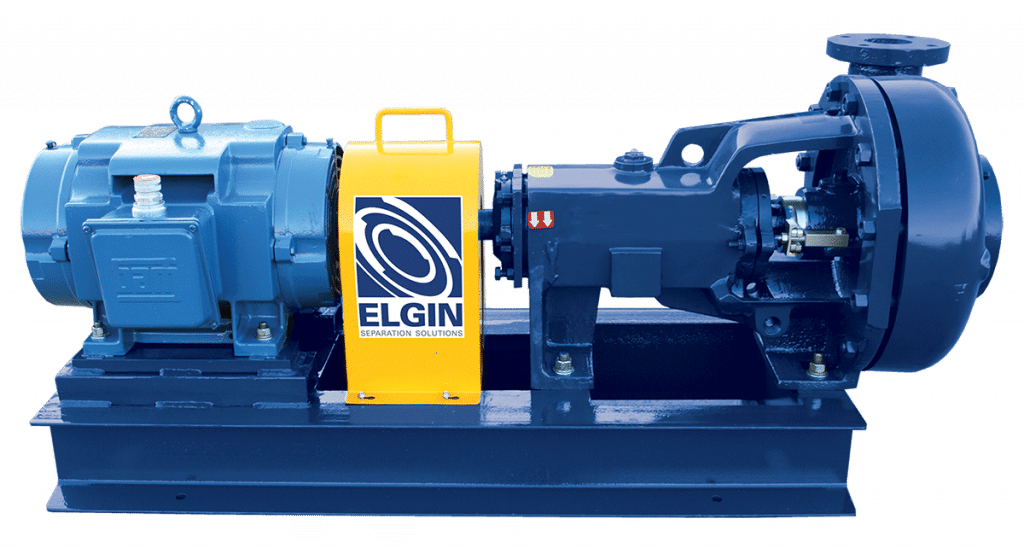

Vision Centrifugal™ Pumps

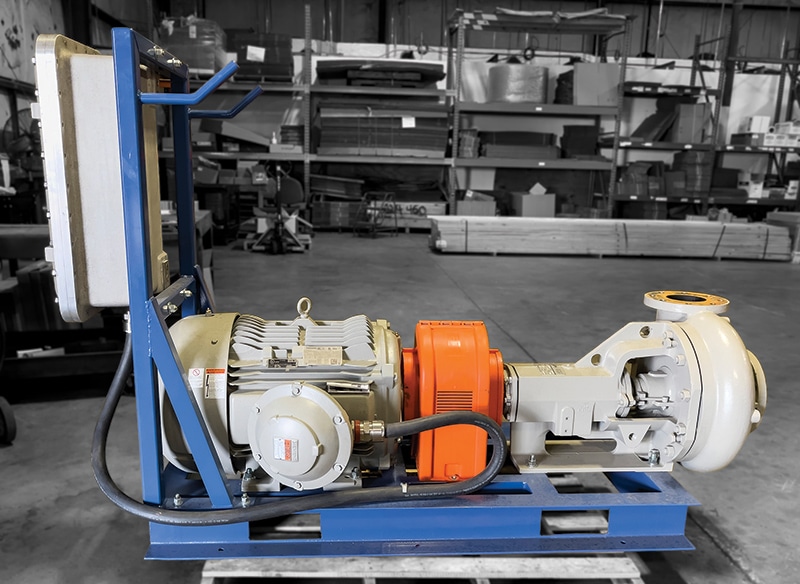

Complete Pump Packages with Integrated Control Panel

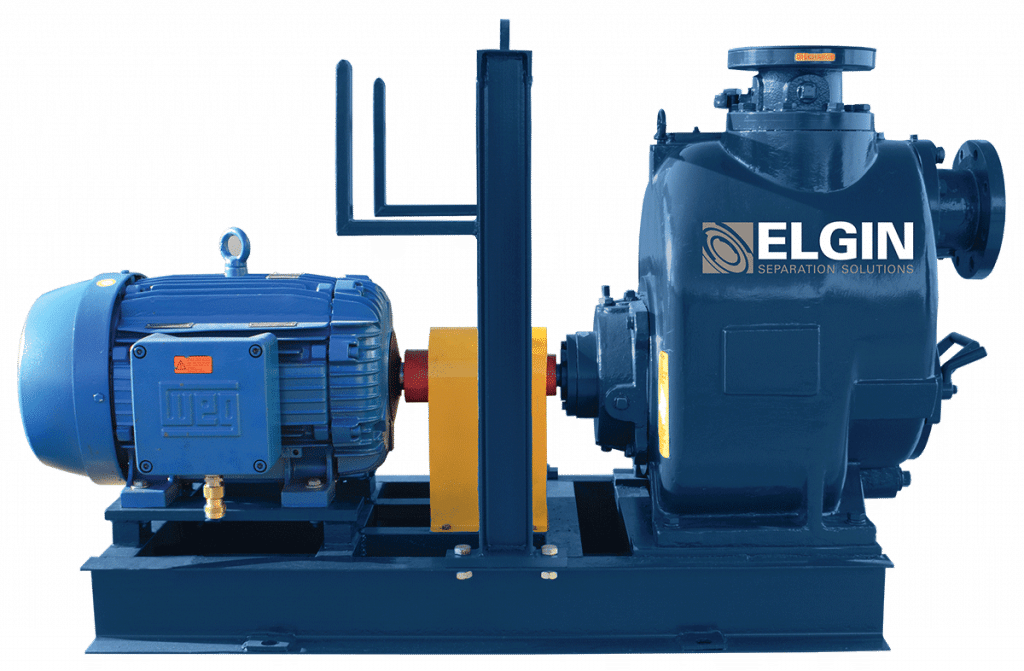

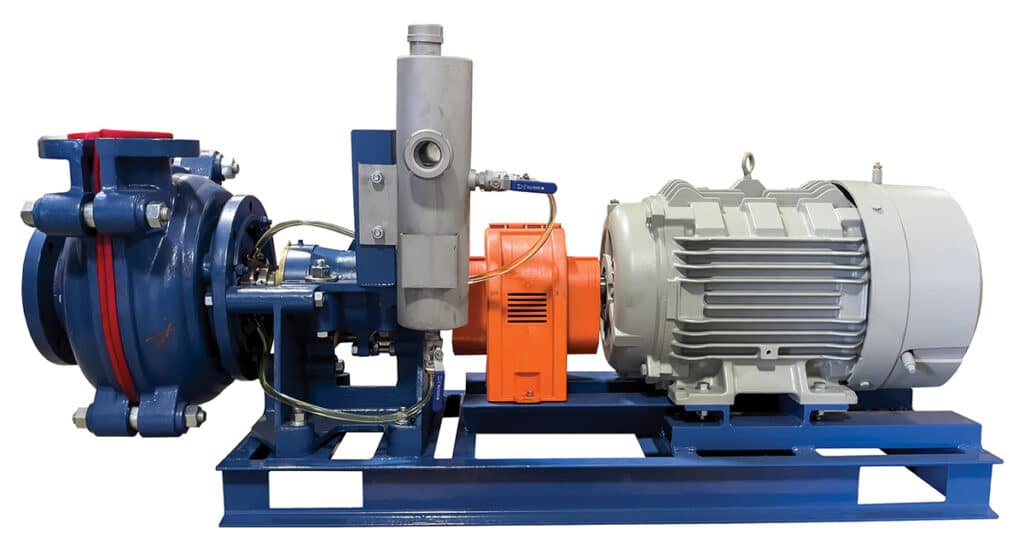

Centrifugal Pumps Overview

Based on the industry’s most field-proven centrifugal pump, Elgin has designed and manufactured with durability and value in mind. Elgin’s pumps are ideal for handling a host of different fluids, most notably abrasive muds. Featuring SKF (or equal) bearings, tungsten mechanical seals, and a wide semi-open impeller design allowing for increased bearing life thru lower axiel thrust.

Elgin knows that an important part of any solids control system includes the use of a high performance centrifugal pump which may have a variety of uses. Elgin’s line of pumps have been engineered for ease of operations, efficiency, and durability. The centrifugal pump is designed to give longer service life through wear pad replacement casing, grease bearing lubrication, labyrinth bearing cap seals, stainless shaft sleeve, and casing nuts. Skid mounted design paired with a premium, Class 1 – Division 1 explosion proof motor, coupling and coupling guard complete the pump package.

Available upgrade options include: optional trims, oil lubrication, shaft sleeves in ceramic coating and 1704 PH hardened, Reverse Rotation Prevention system (RRP), silicon carbide mechanical seal, extra hard iron fluid ends, and lip seals. Starter panels are available upon request.

Centrifugal Pump Features

- Protective shaft sleeve cover reduces wear from abrasive fluids.

- Multiple Applications – Suitable for seawater, freshwater, drilling mud, as well as a host of industrial applications such as cement, mining dewatering, and many more.

- Improved Design – Cast iron frames and the highest quality steel bearings.

- Stainless Steel Casing and wear pad allows ease of maintenance.

- Labyrinth Seals – Labyrinth seals allow for a reduction in bearing contamination and shaft wear.

- Skid Packages Available – Skids come fully powder-coated and include a coupling-guard.

- Wide semi-open impeller creates lower axial thrust for improved bearing life