Tabor Incline Vibrating Screen

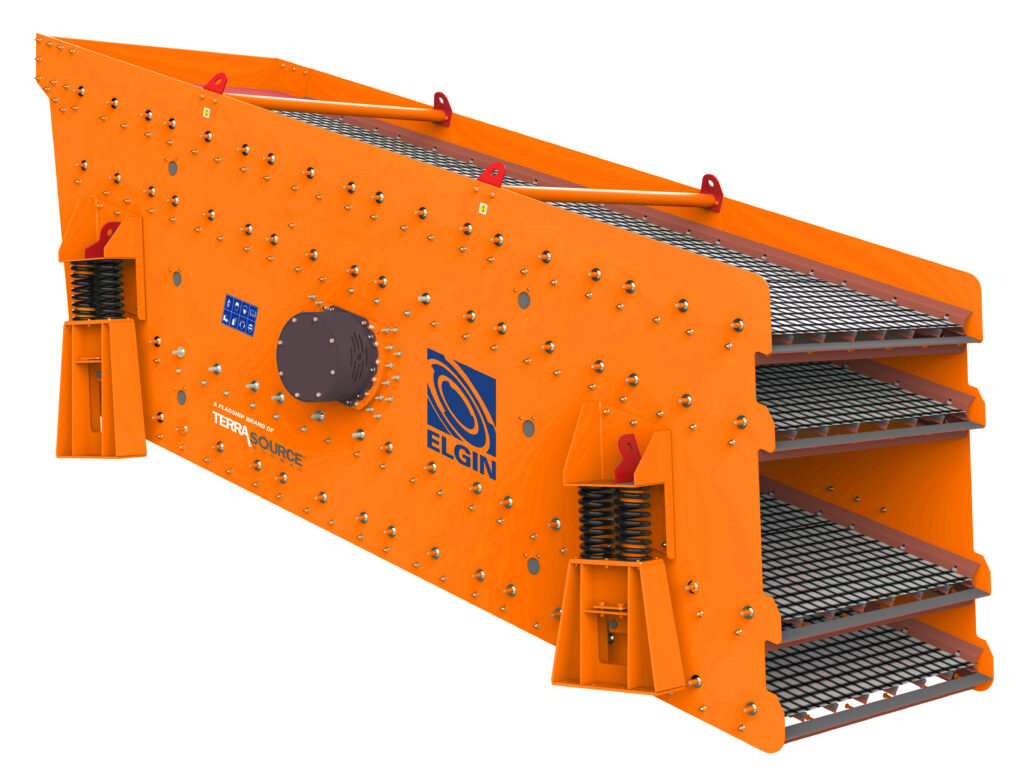

The Tabor™ Incline Vibrating Screen is a rugged, dependable solution for efficient material sizing, desliming, scalping, and rinsing in mining and aggregate operations. Built for high-performance in demanding environments, it offers long-lasting durability and consistent results across a wide range of applications.

Featuring a linear motion design and adjustable vibration settings, the Tabor™ Incline screen ensures precise material stratification and optimized throughput. With single, double, and triple deck configurations, heavy-duty deck frames, and customizable screen media, it’s a versatile and reliable option for coal, sand, stone, potash, and more.

Tabor™ Incline Vibrating Screen Overview

An efficient and effective screening solution built for scalping, sizing, desliming, and rinsing in rugged mining and aggregate applications. Its linear motion design ensures efficient material stratification and superior screening accuracy. Available in single, double, and triple deck configurations, it adapts easily to high-volume operations.

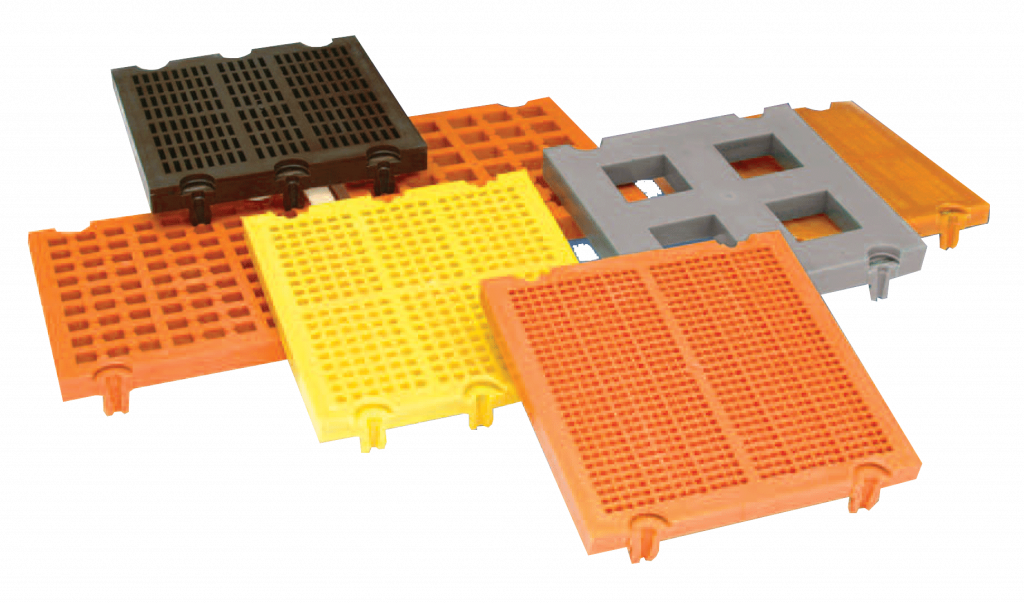

Constructed with heavy-duty 3/8-inch thick A36 steel side plates, huck-bolted assembly, and reinforced deck frames, the Tabor™ Incline is built to handle heavy loads with long-lasting durability. It supports a wide range of screening surfaces, including woven wire, polyurethane, rubber, and punch plates, offering flexibility for various material types and site conditions. Modular screen panels allow for easy customization and replacement.

Additional features include adjustable vibration settings for performance tuning, wear-resistant linings, and optional rubber-lined or ceramic water boxes to extend component life. The dual-shaft drive with Tabor-Thane motors and optional corrosion-resistant paint finishes further enhance reliability. From coal and crushed stone to potash and sand, the Tabor™ Incline Vibrating Screen delivers dependable, efficient operation in any setting.

Features and Benefits

- Lined feed box/back plates

- Dual-shaft V-belt with Tabor-Thane motors

- Huck-bolted assembly on all major body components

- Steel coils for floor mounting

- Single, double, or triple deck options

- Choice of surfaces – woven wire, poly, rubber, perforated plates, or custom

- Reinforced side plates with vertical and longitudinal reinforcing bars

- A variety of paint options for maximum corrosion resistance