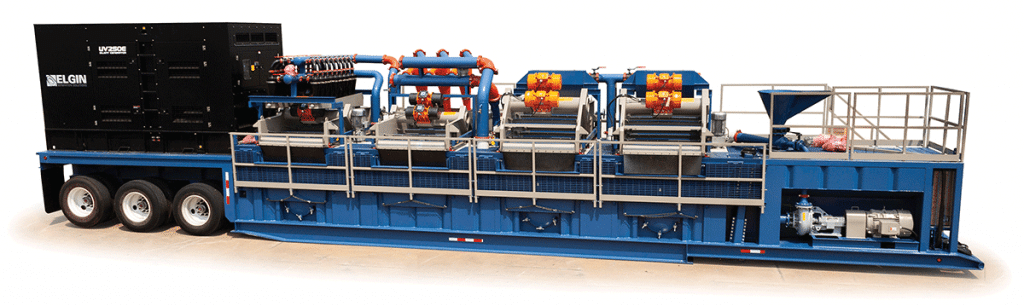

KEMTRON HDD™ 200/250 Pro™ Mud Recycling System

KEMTRON HDD™ 250 Pro-S™ Packaged Mud Unit

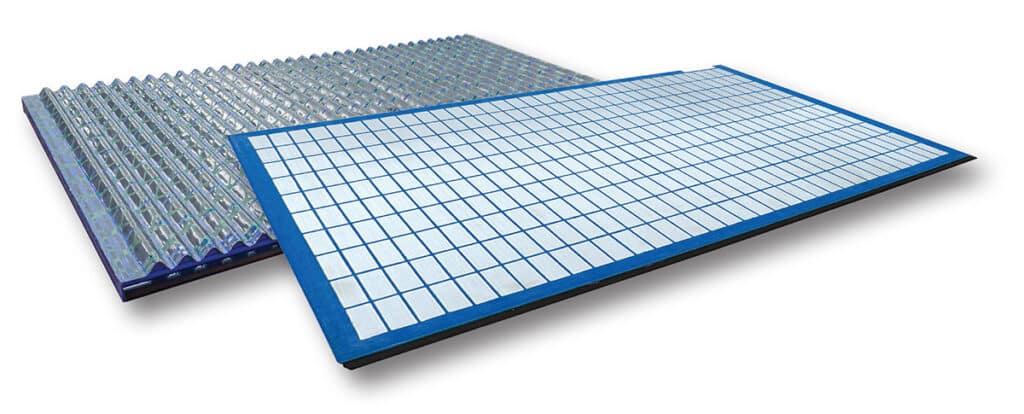

DuroLast 23RB™

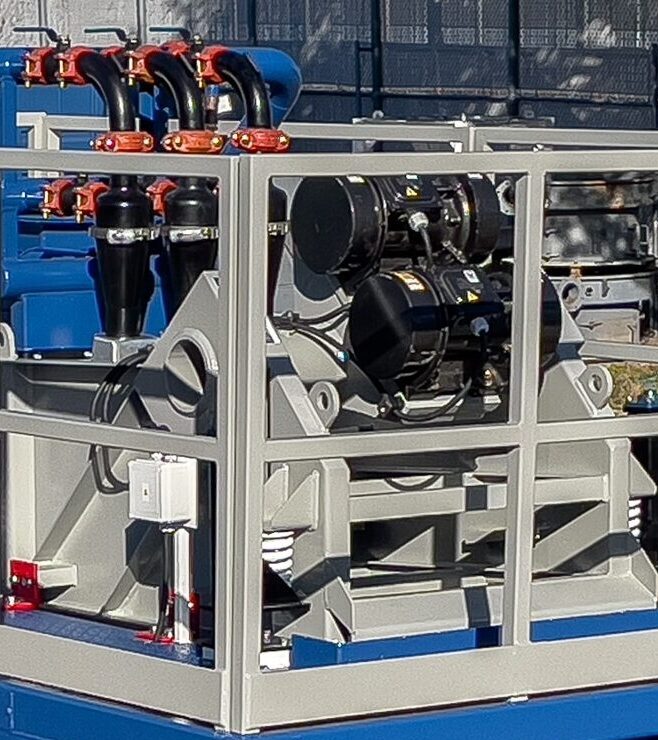

Two dedicated slurry pumps with BlueProof™ liners for desilter and mud gun/transfer operations.

Rear Cuttings Chute

Solids from the shaker are conveyed off the rear of the unit for easy disposal removal.

Mud Hopper

3” Hopper with venturi nozzle and foldout table makes chemical loading safe and efficient.

Vortex™ Hydrocyclones

Up to three 4” desilter hydrocyclones with isolation valves for second stage sand and silt removal.

200/250 Pro™ Overview

Elgin Separation Solutions offers innovative turn-key solutions for today’s operators in the trenchless and waterwell industries. As such, Elgin has become the leading provider of effective packaged fluid recycling systems.

The KEMTRON HDD™ 200/250 Pro™ is ideal for today’s contractors looking to process 65 to 200 gallons per minute (4.1 to 16.6 lps) in a compact, user-friendly design. This system pairs perfectly with operators running rigs like the Ditch Witch® JT20 & JT30, Universal® 22×22 & 32×40 and Vermeer® 20×22 & 36×50 or similar.

Traditional systems offer single pass cleaning. The KEMTRON 200 Pro™ features a multi-pass configuration, allowing each cut to be returned to the primary tank for continuous recirculation. This feature maximizes the shaker and hydrocyclone cleaning performance.

Featuring class leading DuroLast 23RB™ abrasion resistant slurry pumps to maximize pressures needed to ensure proper mixing, optimum hydrocyclone performance, reduced hopper clogging, and adequate transfer pressure back to drilling rig.

Combined with a Tier-4 Final, sound-attenuated, 20kw generator package (optional), 800 or 1,500 gallon tank capacity, heavy-duty dual-axel trailer and fold-out hopper table, the KEMTRON 200 Pro™ packaged fluid reclaimer is the perfect solution for your solids control needs.

Features and Benefits

- Multi-pass cleaning system maximizes shaker and hydrocyclone performance.

- Largest screen surface area, 22 sq. ft., outperforms competitors, in its class, in sand and silt removal.

- Most efficient tank agitation per unit volume of mud ensures complete mixing performance.

- Dedicated DuroLast™ pumps with BlueProof™ liner, inset on the side of the tank for easy maintenance, provide independent transfer/mud circulation/hopper, and desilter operations.

- Elgin’s tanks are fully lined with a phenolic lining to maximize tank life and reduce the effects associated with the circulation of abrasive / erosive solids to extend equipment life.

- Custom configurations in tank capacity, trailer/skid design, and number of hydrocyclones, sets Elgin apart in meeting its customers needs.