Turn-Key Solutions Provider

Over the years, Elgin has evolved beyond a traditional equipment manufacturer of liquid/solids separation, material classification, dewatering, waste management, and material handling products.

Today, Elgin is driven to meet customer needs in finding the ideal solution suitable for any project requirement. Taking the basic capital equipment procurement process and turning it into a relationship that extends through the entire life of the products, systems, and services provided is Elgin’s primary focus.

Elgin’s in-house engineering team is dedicated to solving the most complex problem for your operational needs. Offering complete 2D & 3D design and detailing, general assembly drawings, and process flow descriptions, to name a few. Whether you are looking for a stationary or mobile solution, Elgin’s team is ready to design your next project.

Integrated Cuttings Waste Management / Oil Recovery Plant

Elgin’s Integrated Cuttings Waste Management System has been designed to treat oil-based raw cuttings slurry, generated by the oil and gas drilling industry, by utilizing chemically-assisted mechanical separation. Via the deployment of microemulsions, Elgin’s system uses liquid/solid separation technologies to remove coarse, then fine, suspended solids respectively. Once the coarse and fine solids have been removed from the slurry, the residual microemulsion will enhance phase separation of the oil and water, prior to being transferred to a oil & wastewater collection system.

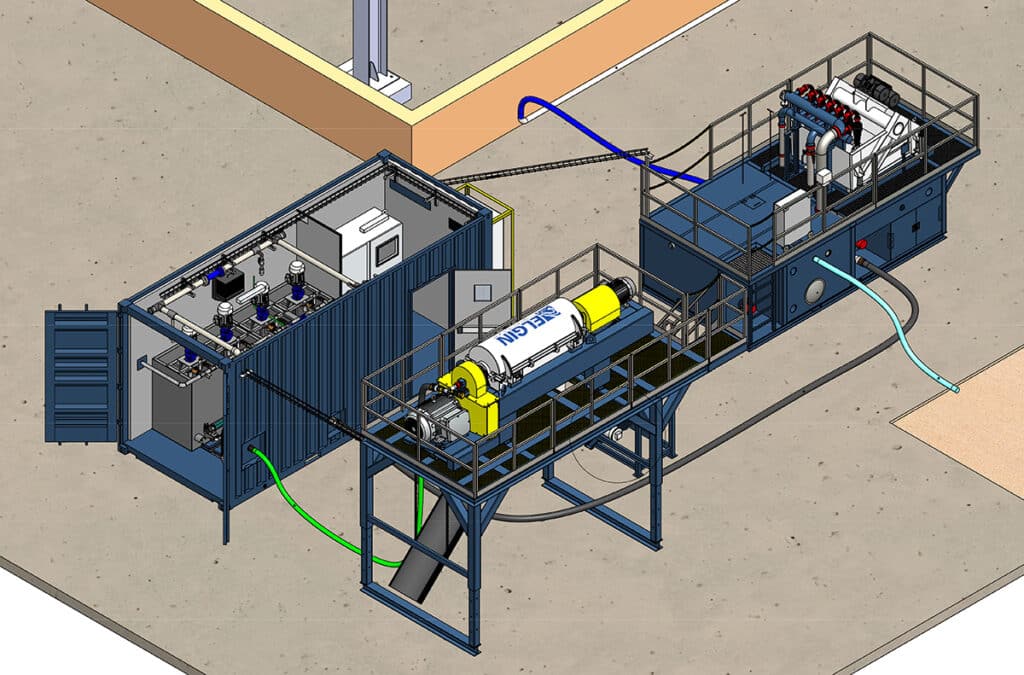

Ultra-Fine Precious Metals Recovery Solution

This ultra-fine precious metals recovery unit is a perfect example of Elgin’s unmatched capabilities in the systems integration and custom control interfaces. Featuring two high-speed ESS-1967HD2 decanter centrifuges, dedicated centrate catch tanks, and a containerized polymer injection system with control room.

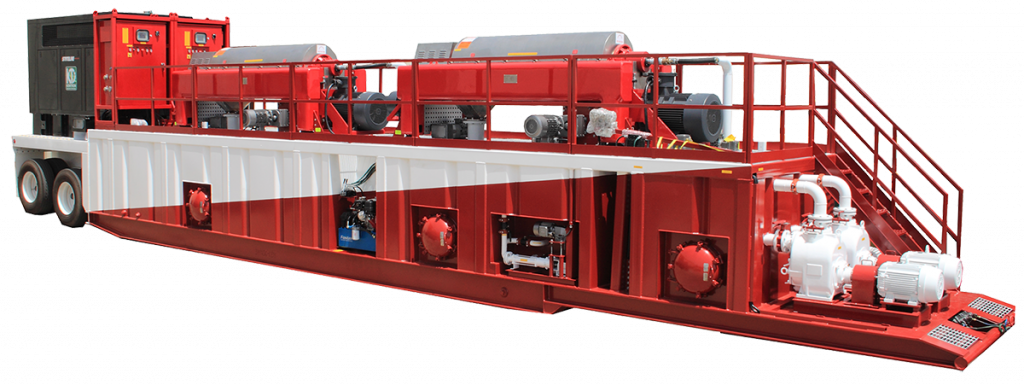

Mobile Coarse Solids Dewatering Plant

Elgin’s Mobile Coarse Solids Dewatering System has been designed to treat water-based and oil-based waste cuttings slurry, generated by the oil and gas drilling industry, by utilizing a combination of mechanical separation technologies. This system incorporates individual skid-mounted systems and a 20’ high-cube containerized control room allowing handling to be achieved via transport trucks. As dictated by the feedstock parameters, a de-emulsifying microemulsion package may be deployed.

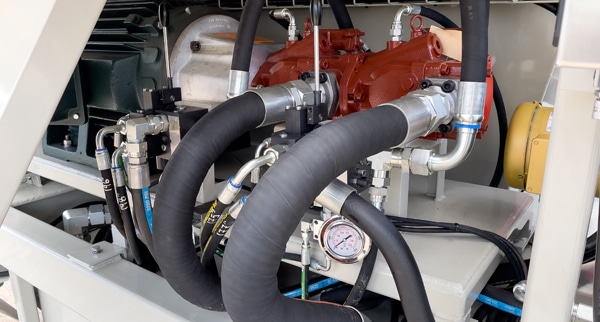

Mobile Track Driven Fluid Recovery System

This custom KEMTRON 200CR™ is capable of processing up to 200 gallons per minute and features a hydraulic track mobility system perfect for maneuvering in tight locations. Featuring a double-deck shaker, hydrocyclone manifold, dedicated 118 series centrifugal pumps, and 100 kW tier-4 Final generator.

Waste Oil Sludge Recovery System

Custom designed Waste Oil Sludge Management System featuring onboard decanter centrifuge, disc-stack centrifuge, polymer injection system, progressive cavity feed pump, and solids discharge screw conveyor.

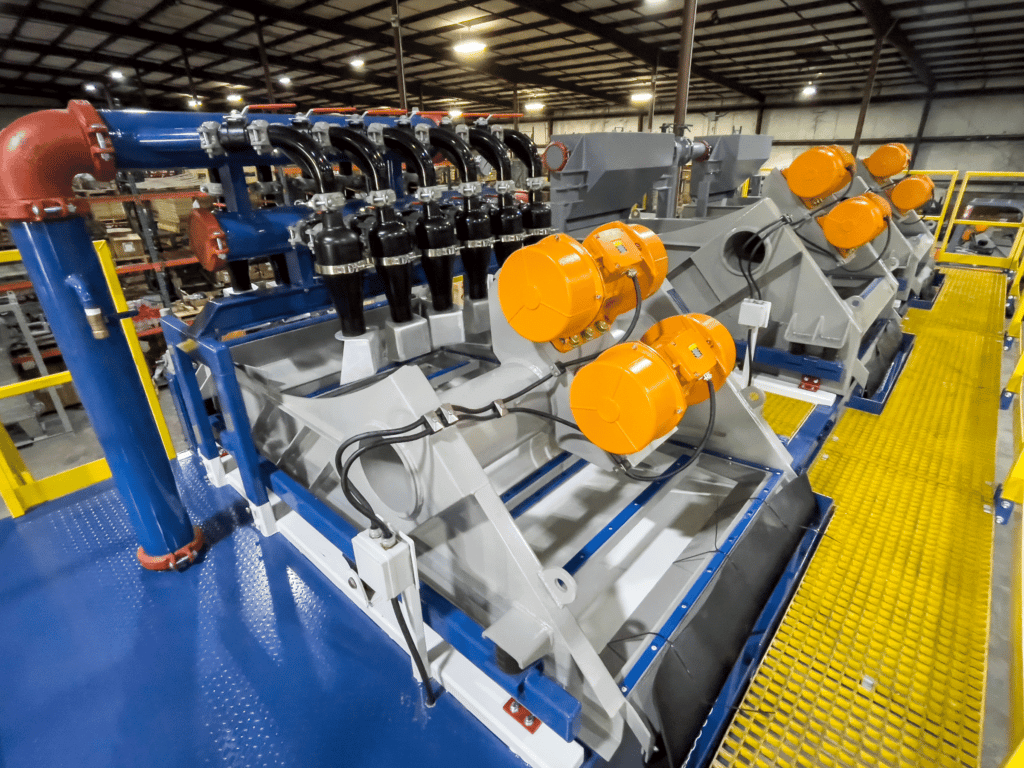

Waste Cuttings Treatment Solution

This turn-key waste cuttings treatment system is designed to remove solids down to five microns while reducing moisture on solids below 20%. Featuring two (2) 6-panel, double-deck Hyper-G™ shakers, two (2) ESS-1967HD2™ high-speed decanter centrifuges, solids discharge screw conveyor system, dedicated slurry pumps, two (2) partitioned centrate tanks, and containerized central control room.

Industrial Wastewater Treatment Plant

Elgin offers industrial solutions to meet the needs for effective chemical and solids treatment, for even the most stringent water quality requirements. Elgin designs modular, expandable, closed-loop industrial wastewater systems to treat a number of Contaminants of Concern (“COC’s”), specifically coarse and fine suspended solids, free heavy oils, emulsified fine oils, and dissolved solids and salts.

Hydrovac Waste Treatment Plant

Elgin’s Hydrovac Waste Treatment System has been designed to treat water based slurry, generated by the trenchless/wastewater industry, by utilizing chemically-assisted mechanical separation. Via the deployment of polymers, Elgin’s system uses liquid/solid separation technologies to remove coarse, then fine, suspended solids respectively. Once the coarse and fine solids have been removed from the slurry, the recovered centrate will be transferred to a wastewater collection system. Dried discharged solids are then hauled off for disposal at a local collection area.

Metal Recycling and Fluid Recovery Plant

This custom turn-key-solution was designed for a metal recycling and steel manufacturing company with the goal of cleaning their metal of any debris and recovering clean fluids to be reused. This system includes a dirty and clean fluid poly tank unit, a stand alone polymer injection unit, a shaker skid unit, and an ESS-1967HD2 decanter centrifuge.

Custom Solutions Incorporating Existing Assets

Elgin Separation Solutions can take your existing capital equipment and create a mobile, skid or containerized system to suit your needs. Take your centrifuge and turn it into a mobile dewatering and waste oil treatment system. Let us mount your shakers onto a mobile tank system and increase your services with mobile recycling capabilities. Call us today to discuss how we can elevate your company’s services using your existing assets.