Polymer Injection / Chemical Mixing Systems

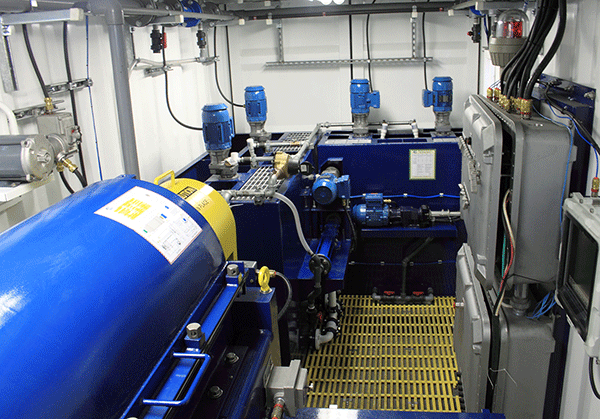

20-Foot Containerized Polymer Injection System

20-Foot Polymer Injection System

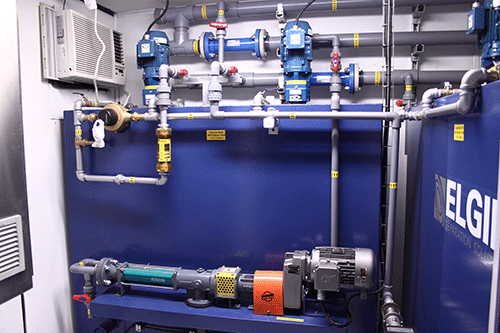

10-Foot Containerized Polymer Injection System

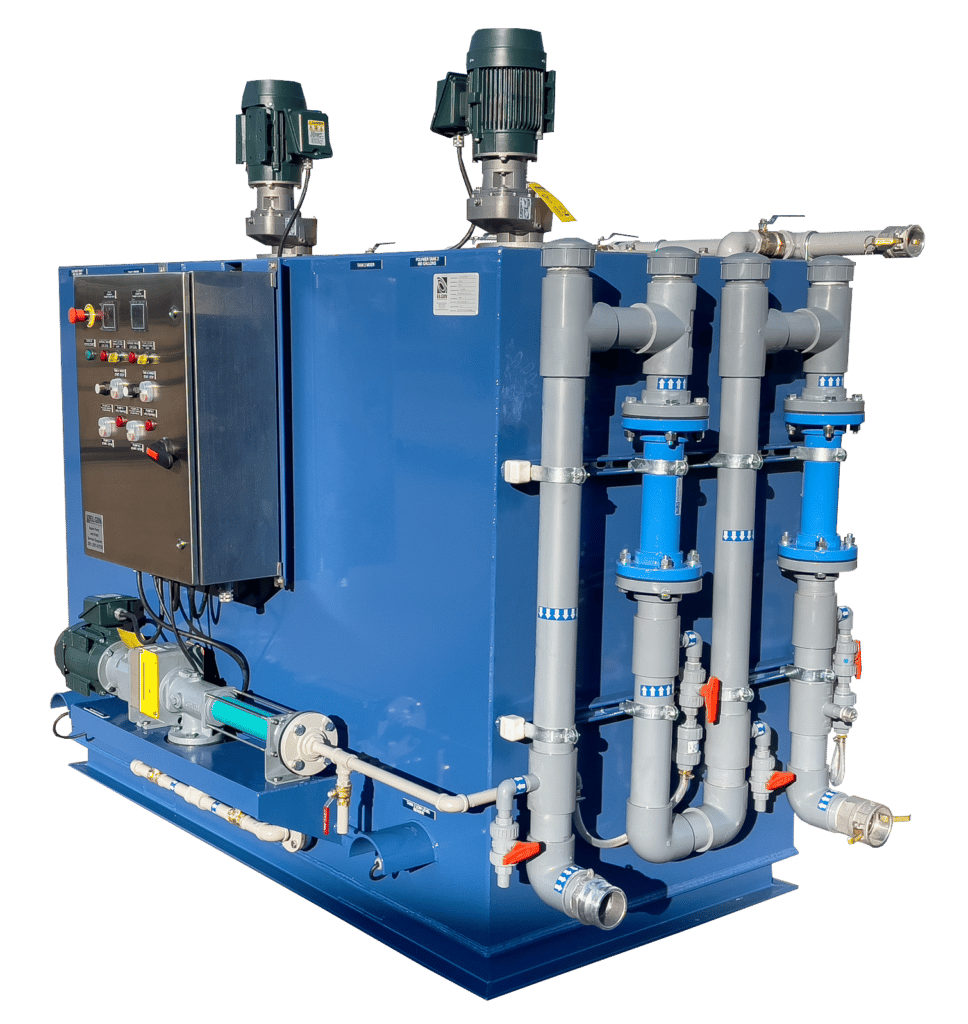

Elgin's Independent Polymer Injection System

This custom independent polymer injection system maximizes liquid/solid separation with 2 polymer pumps that connect to a hydration manifold. Further separation occurs as solids and liquids are sent into 2 polymer tanks for efficient dewatering. Lastly, with a dedicated control panel, operators are able to monitor this unit from start to finish. Elgin remains an industry leader in bringing mobile solutions to the toughest solids management problems.

Polymer Injection Overview

Polymer injection is key to efficient liquid/solid separation when dewatering in a ‘closed-loop zero discharge’ environment. Furthermore, the addition of polymers during operation allows the operator, to recover water from the fluid maximizing profits.

Dewatering also maximizes drilling fluid recovery, ultimately lowering overall mud costs as well as disposal and transportation expenses. Furthermore, Elgin’s systems improve mud properties therefore improving the rate of penetration. With a “zero-discharge” or “closed-loop system” rigs can operate without mud pits, therefore reducing the location footprint and environmental impact.

Learn More about our Different Dewatering Injection Systems by Contacting an Elgin Representative today!

Features and Benefits

- Dedicated Progressive Cavity Pumps for Polymer Injection

- Top-Mounted Tank Agitators

- In-Line Static Mixers

- Flow Meter for Operation Tracking

- Twin-Line Manifold for Multiple Fluid Feeds

- Optional Climate Control HVAC System

- Touch-Screen Control panel with Built in Wi-Fi Network for Remote Monitoring

- Fresh Water Intake Dilution Gauge

- Fully containerized system with multiple tanks for continuous polymer mixing without system downtime.

- Dual injection manifolds allow for fluid processing to multiple centrifuges.

- Proprietary control panel with touch-screen interface controls entire system for accurate mixing and processing capabilities.

- Built-in flow meters monitor and log daily processing for increased productivity.

- Tank level sensors add a level of protection to prevent injection pumps from running dry.