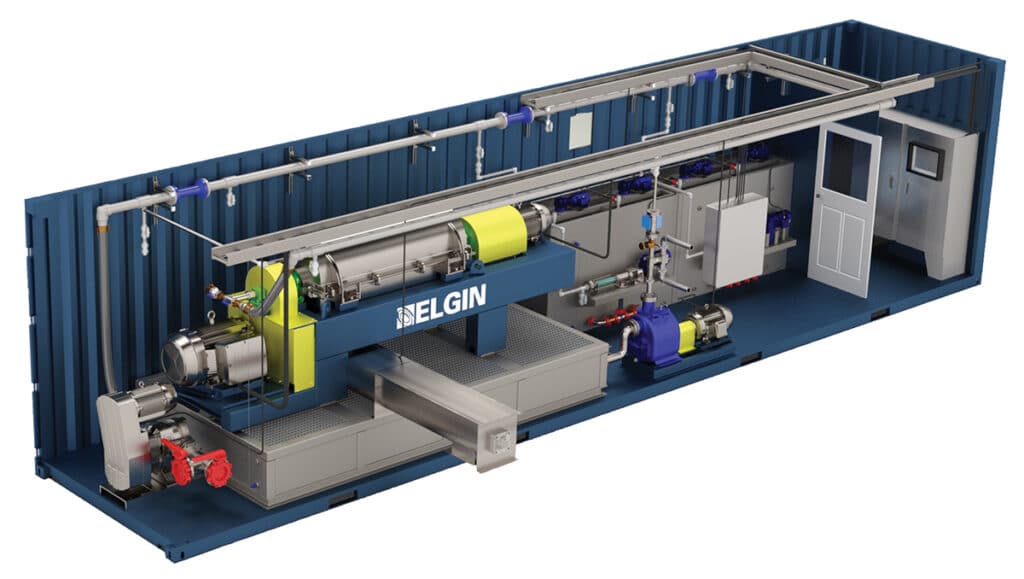

ClearWave™ Containerized Dewatering & Waste Oil Treatment Systems

A dewatering system is used in the removal of water from solid material or soil by wet classification, centrifugation, filtration, or similar solid-liquid separation processes. As the drilling industry is regulated by a myriad of environmental regulations that continue to become increasingly more stringent, having the right solids control and fluid dewatering/waste oil treatment system have become vital to successful drilling operations. Fluid dewatering systems presents a great deal of benefits and advantages. One such benefit includes discharge compliance, in which many cases result in a “zero-discharge” or “closed-loop system.” In addition, the importance of treating waste oil from the drilling fluid is vital to maximizing profits.

Dewatering also maximizes drilling fluid recovery, ultimately lowering overall mud costs as well as disposal and transportation expenses. Furthermore, with these systems, mud properties improve and as mud properties improve, so too does the rate of penetration. With a “zero-discharge” or “closed-loop system” rigs can operate without mud pits, therefore reducing the location footprint and environmental impact

ClearWave 40™ Dewatering System

ClearWave 20™ Waste Oil Treatment System

ClearWave 40™ Dewatering System

Introducing Elgin's New ClearWave 10™ Foot Containerized Dewatering System

Dewatering System Overview

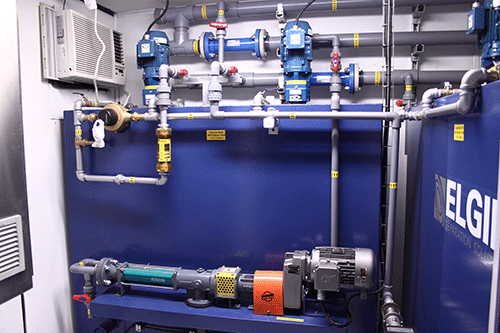

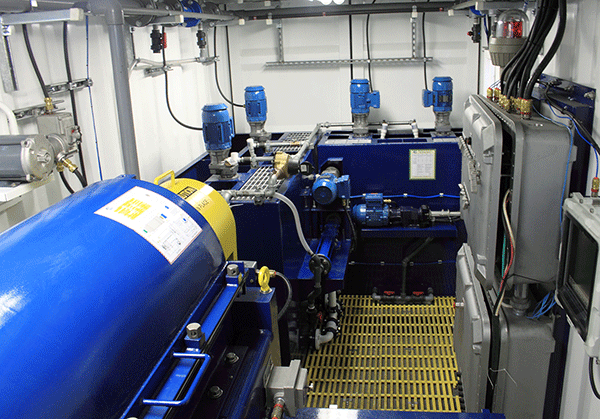

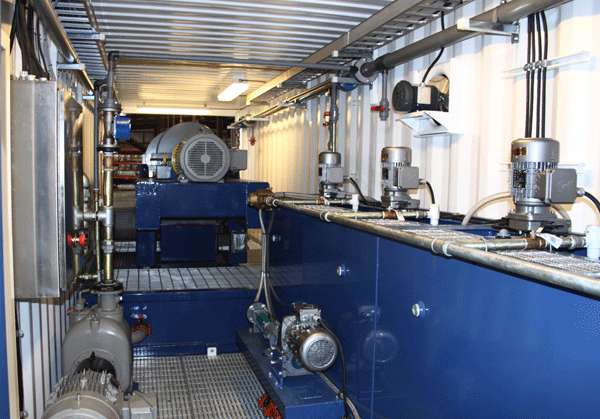

For almost 30 years, Elgin has been designing solids management and dewatering systems for the most demanding environments. With this experience, Elgin has designed a variety of Containerized Dewatering Units built inside double-door, high-cube shipping containers. These units are designed with the customer in mind by being mobile and compact. Furthermore, they also incorporate sophisticated graphical user interfaces, chemical additive injection systems, Apex 9VFD, Apex 14MVD, Apex 16FHD, or Apex 19VFD decanter centrifuge, and in-line mixing systems.

By utilizing proprietary polymer hydration manifolds, the polymer enhanced flocculation and coagulation of colloidal and ultra-fine drilled solids can be efficiently removed with a decanter centrifuge.

This versatile unit can be customized by our engineering team to meet any specific needs or challenges. It may be operated as a stand-alone device or can be incorporated as the cornerstone of a sophisticated closed-loop solids control and waste management treatment system. Systems can be climate controlled and insulated, upon request.

Contact Elgin and let our in-house engineering team custom design the perfect system for your operations.

System Features

10 Foot Dewatering System

- Apex 9VFD™ Decanter Centrifuge.

- 150 Gallon (568 liter) Partitioned Centrate Tank.

- Two (2) 150 gallon (568 liter) Chemical Dosing Tanks.

- Dedicated Polymer Injection Pumps.

- Solids Discharge Screw Conveyor.

- Progressive Cavity Pump to Feed Centrifuge.

- Self-Priming Pump for Dilution and Transfer Function.

- Top Mounted Agitators on Chemical Tanks.

- HMI Touch Screen Control Panel.

20 Foot Dewatering System

- Apex 14MVD™ or Apex 16FHD™ Decanter Centrifuge.

- Partitioned Centrate Tank with Level Sensors.

- Solids Discharge Screw Conveyor.

- Polymer Mixing Tanks with Top Mounted Agitators.

- Dedicated Polymer Injection Pumps.

- HMI Touch Screen Control Panel.

- Progressive Cavity Pump to Feed Centrifuge.

- Self-Priming Pump for Dilution and Transfer Function.

40 Foot Dewatering System

- Apex 19VFD™ Decanter Centrifuge.

- Isolated Mud Testing Lab.

- Polymer Mixing Tanks with Top Mounted Agitators.

- Dedicated Polymer Injection Pumps.

- HMI touch Screen Control Panel.

- Progressive Cavity to Feed Centrifuge.

- Solids Discharge Screw Conveyor.

- Self-Priming Pump for Dilution and Transfer Function.