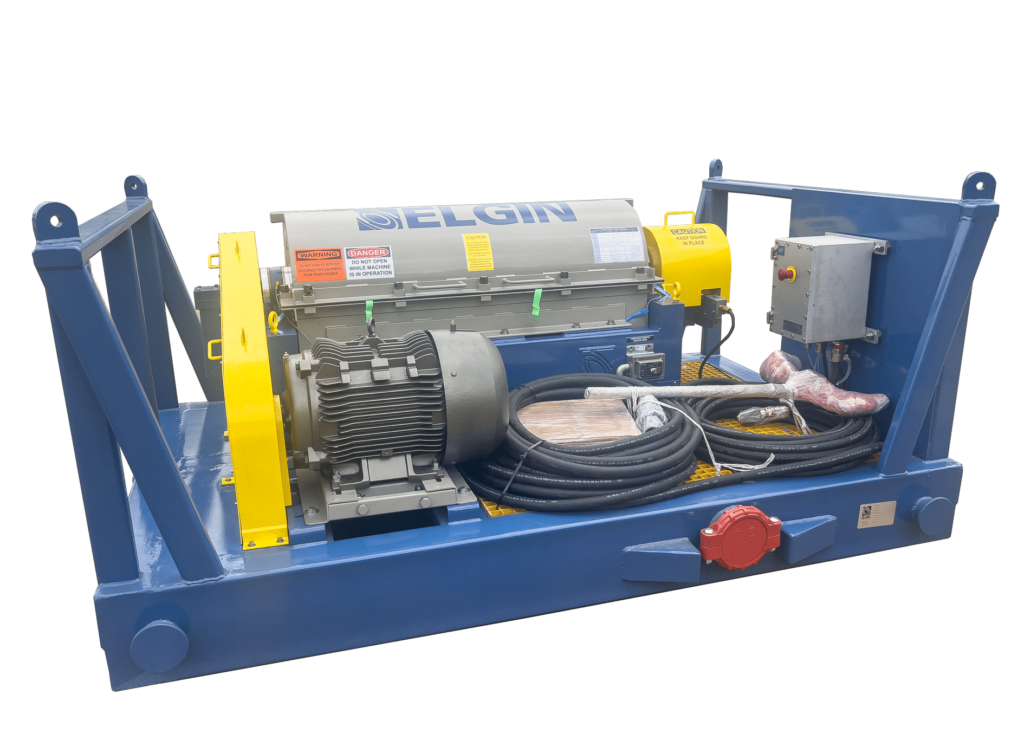

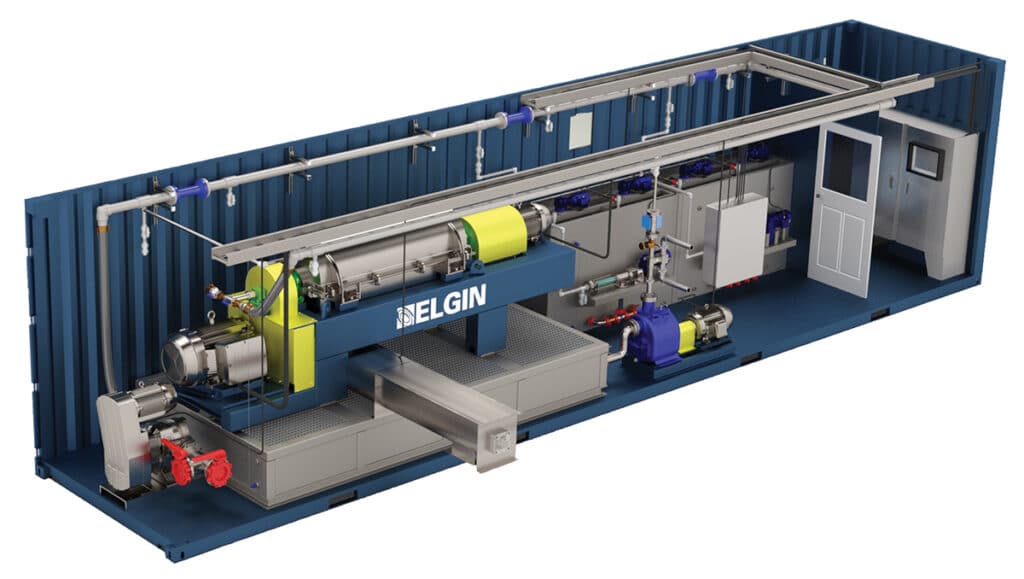

Elgin’s Apex™ 14 Decanter Centrifuge: Precision-Engineered for Superior Separation

When high-performance liquid/solid separation is mission-critical, the Apex 14 decanter centrifuge from Elgin Separation Solutions stands above the rest. Purpose-built for demanding applications in fluid recovery, dewatering, waste management, and natural resource recycling, the Apex 14 combines robust engineering, advanced automation, and proven reliability. With a maximum G-force of 2,100 G’s, optimized bowl design, and industry-leading gearbox configurations, Elgin delivers unmatched efficiency and performance — minimizing downtime and maximizing processing yields.

Discover the next generation of horizontal centrifuge technology with the Apex 14 — engineered for results that count.

Features & Benefits of the Apex™ 14 Centrifuge

Precision-Built Performance

- 14″ diameter x 50″ stainless steel rotating assembly.

- 2,100 G-force and 3,250 rpm speed capacity for superior solids-liquid separation.

Durable, Heavy-Duty Construction

- Fully stainless-steel bowl and conveyor for corrosion resistance and extended service life.

- Premium pillow block bearings and heavy-duty carbon fiber poly-chain drive for reliable, low-maintenance operation.

Advanced Control Systems

- Integrated HMI touch-screen VFD control panel for complete system management.

- Cruise Control™ automation minimizes operator oversight while maximizing output.

Maximum Operator Safety

- Standard safety interlocks including lid sensors, vibration switches, thermal protection, and emergency stop systems ensure safe operations under all conditions.

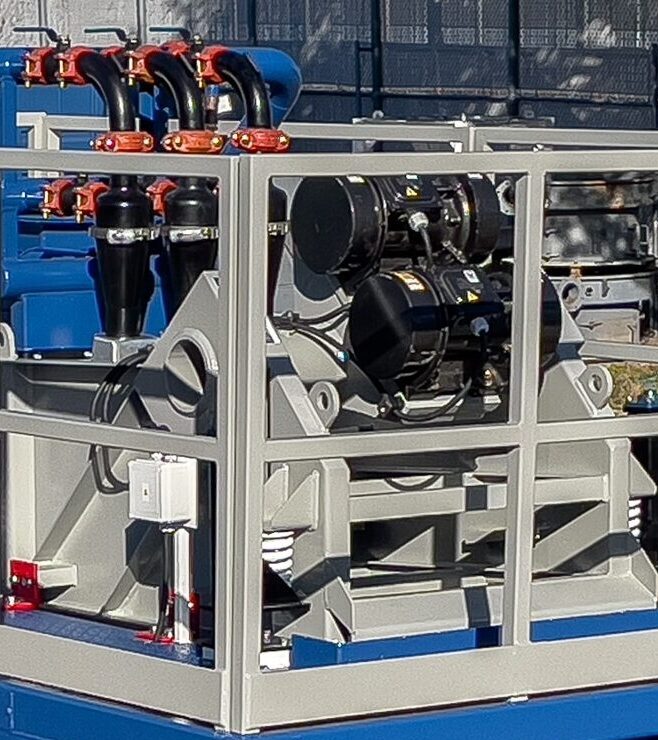

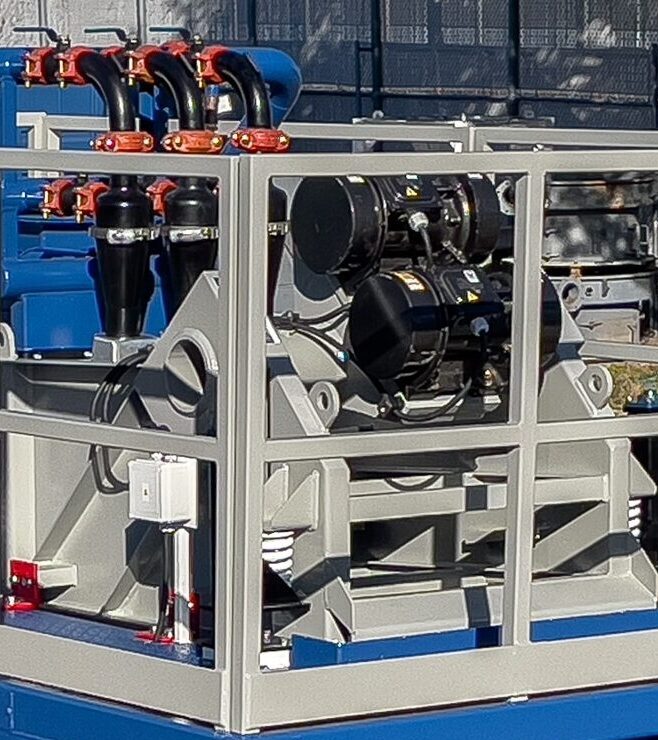

Flexible Deployment

- Field skid, trailer-mounted, and containerized solutions available, customizable with integrated pumps, conveyors, and generators.

Apex 14™ Models

Apex 14FHD™

Patent-Pending Electronically-Controlled, Hydraulic-Driven with 75 HP power motor and variable speed hydraulic main drive and back drive configuration.

Apex 14FVFD

Full variable speed driven centrifuge with 50 HP main drive motor and 15 HP back drive motor.

Apex 14MVD

Manual Variable Drive

Apex 14™ Features

- Carbon fiber poly-chain belt driven system.

- Four, stainless-steel, epicentric, liquid-end discharge ports.

- Four, wide-mouthed, tungsten carbide solids discharge ports and plows.

- Premium SKF™ bearings installed in precision-machined pillow blocks.

- Available in manual variable (MVD) or full variable (FVD) with back drive configurations.

- 2,100 maximum G-force available.

- Up to 3,400 maximum rotational speed.

- 304 stainless-steel rotating assembly bowl construction.

- 52:1 or 125:1 planetary gearbox available upon request.

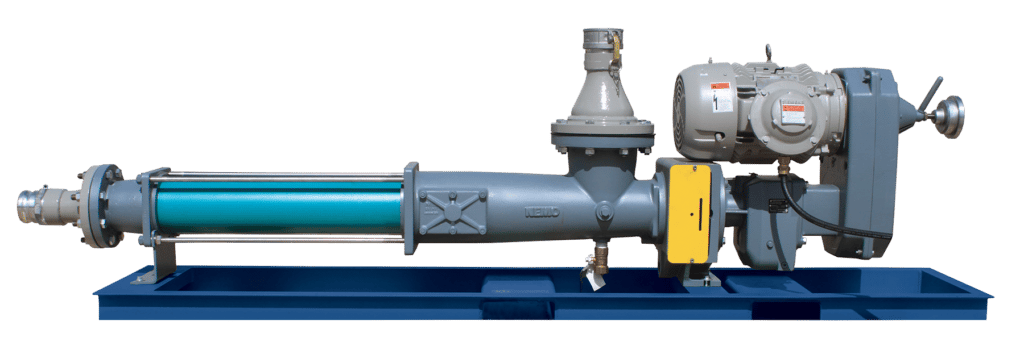

DuroLast 23RB™

Two dedicated slurry pumps with BlueProof™ liners for desilter and mud gun/transfer operations.

Rear Cuttings Chute

Solids from the shaker are conveyed off the rear of the unit for easy disposal removal.

Rear Cuttings Chute

Solids from the shaker are conveyed off the rear of the unit for easy disposal removal.

Rear Cuttings Chute

Solids from the shaker are conveyed off the rear of the unit for easy disposal removal.

Mud Hopper

3” Hopper with venturi nozzle and foldout table makes chemical loading safe and efficient.

Vortex™ Hydrocyclones

Up to three 4” desilter hydrocyclones with isolation valves for second stage sand and silt removal.

Elgin’s ClearWave Dewatering Systems are the perfect solution.