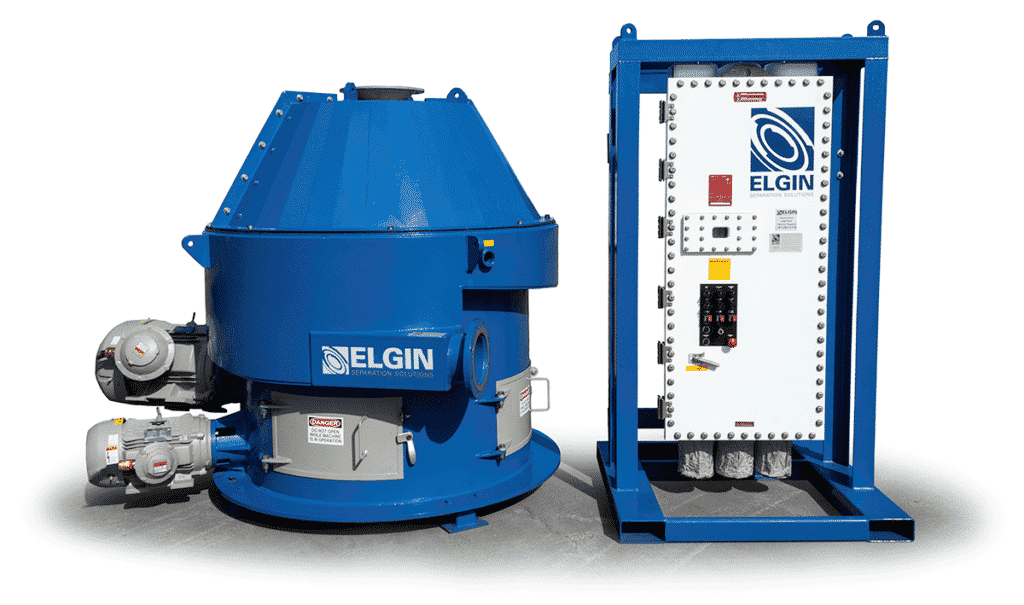

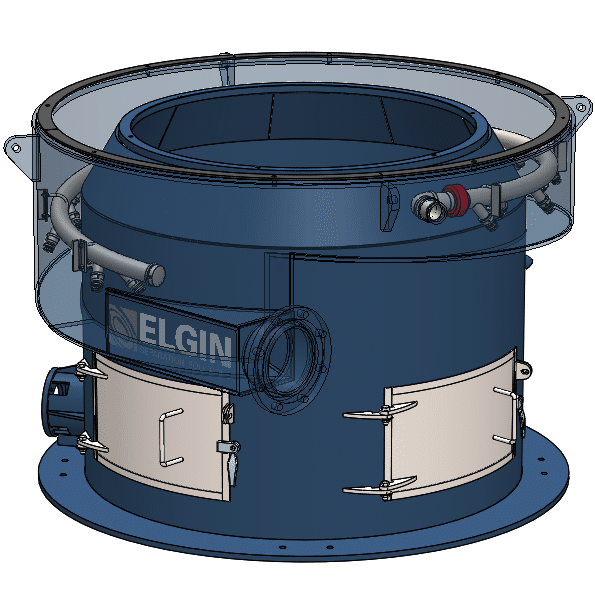

CSI-D4 Cyclone Pro™ Vertical Cuttings Dryer

Elgin’s CSI-D4™ Vertical Cuttings Dryer is the world’s first, patented, dual-drive dryer. This technology allows operators the ability to adjust the performance of the dryer based on the nature of the solids being fed to it. Using a combination of proprietary gear boxes, operators can adjust both the applied G-force and the dwell time between the scraper flites and the screen. This technology allows the CSI-D4™ Vertical Cuttings Dryer to be used in both oil-based and water-based drilling fluid environments.

Elgin Separation Solutions’ CSI-D4™ VCD incorporates several unique features, including an automatic shut-off system to protect the gearbox and individually balanced rotating components, when high temperatures are identified, to ensure trouble-free operation.

CSI-D4 Cyclone Pro™ Overview

Typical flow-line shaker cuttings maintain a moisture level on average between 15% and 20%. When properly managed, Elgin Separation Solutions CSI-D4 Cyclone Pro™ Vertical Cuttings Dryer can lower the moisture content on waste cuttings below 4%, in some cases 1%. This can be done while managing up to 80 tons (73,000 kilograms) per hour of waste cuttings, depending on operating conditions.

Elgin’s patented dual-drive design provides operators the ability to adjust the main drive and back drive speed to dial in the optimal differential achieving maximum solids dryness while recovering thousands of gallons of drilling fluid typically lost in disposal. Like a decanter centrifuge with a back drive, the CSI-D4 Cyclone Pro™ operates on a VFD platform allowing on demand speed adjustments during operation.

Traditional cuttings dryers were only capable of processing oil-based waste cuttings. Elgin’s CSI-D4 Cyclone Pro™ can process both water-based and oil-based cuttings without needing to replace the screens or flites. Additionally, the vertical cuttings dryer requires no active lubrication system or belt drive assembly making it the perfect solution for waste cuttings management.

CSI-D4 Cyclone Pro™ Features

Perfect Solution for Managing Water-Based and Oil-Based Waste Cuttings

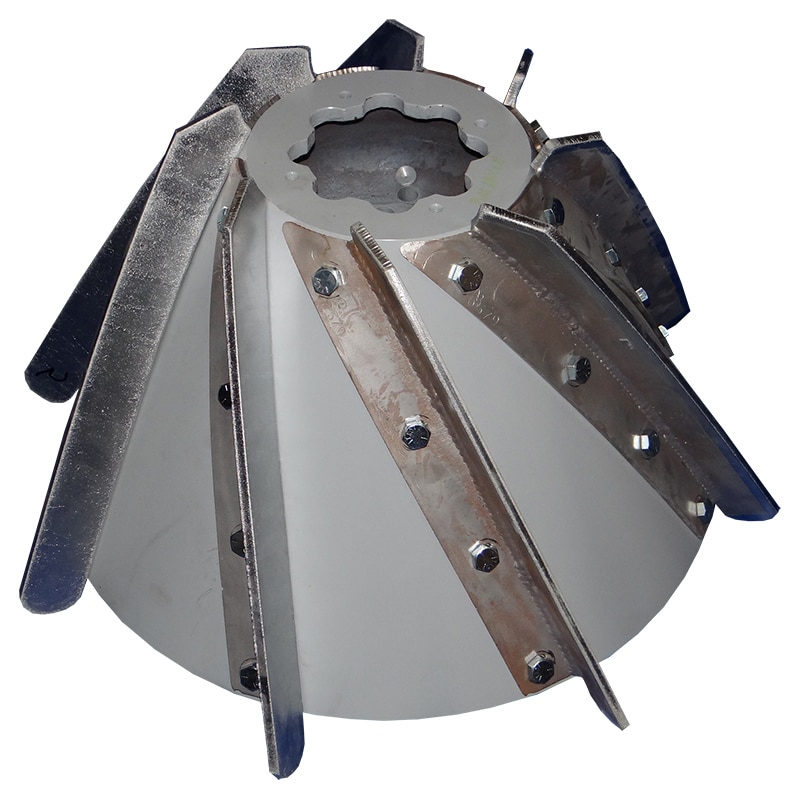

Engineered Flites

Various blade materials and coatings available

(Tungsten and Hard Chromed)

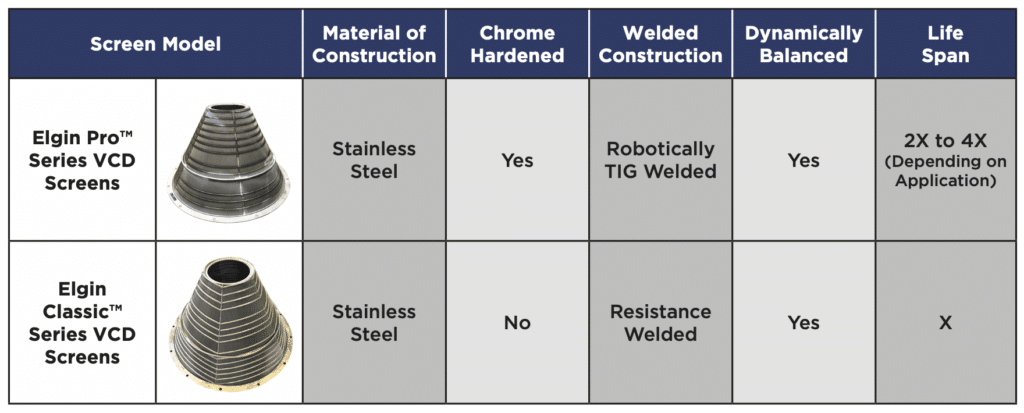

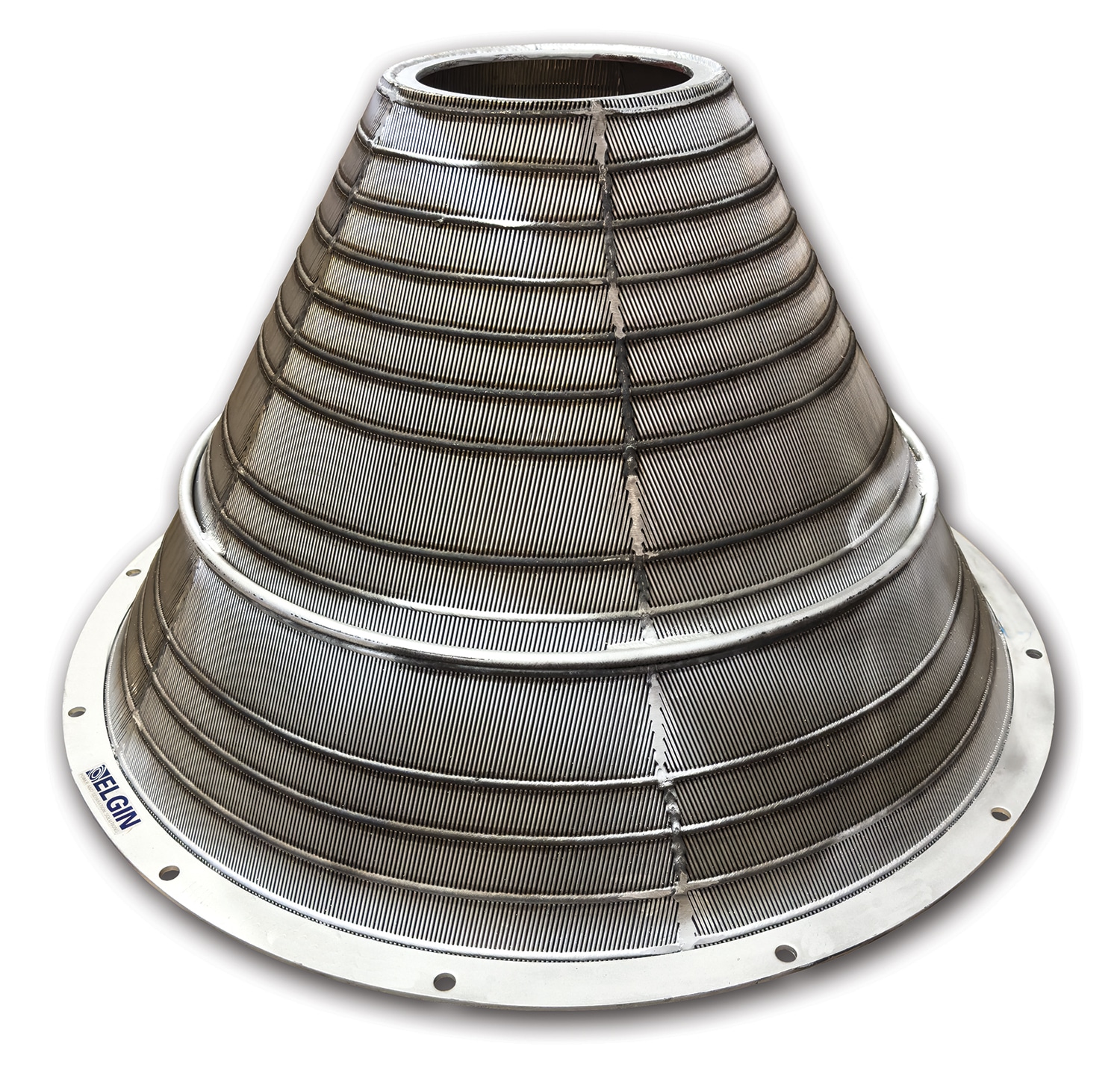

Screen Design

Fully TIG welded and

chromed screens can help customers extend screen life as long as a year

Spray Bar

Integrated spray bar into the launder section ensures VCD can withstand longer operating periods between service

Conical Launder

Cork-screw launder design made to significantly lower the risk of a back-up within the VCD

Access Hatch

Three hatches located around the body for cleaning of the solids discharge section and maintenance

VCD Resources

- CSI Cyclone™ VCD Product Line Brochure

- CSI-D4 Cyclone Pro™ VCD Product Presentation

- CSI Cyclone™ VCD Product Presentation

- CSI-D4 Deployment Case Study

- VCD Screen and Flite Selection Guide

- VCD Safety Hazards White Paper

- VCD Application in Solids Control Program

- CSI Cyclone Pro™ Turn-Key Waste Cuttings System

- CSI-D4 Cyclone Pro™ Package System Video

- CSI™ VCD Turn-key System Press

- Request A Quote