Decanter Centrifuge

Looking to optimize your product recovery or enhance the efficiency of your zero-discharge, closed-loop system? Elgin’s field-proven decanter centrifuges provide the ideal solution for liquid/solids separation and dewatering operations. With over 550 centrifuges installed globally, Elgin’s dewatering centrifuge solutions are trusted for performance and reliability across a range of industries.

A decanter centrifuge is a high-performance mechanical device designed to separate solids from slurries, commonly used in industrial applications like oil well drilling. In this process, centrifuges help to condition drilling fluids by separating them into high-density and low-density streams through accelerated sedimentation. As the fluid moves through the rapidly spinning bowl, centrifugal force pushes heavier particles to the outer wall. A specialized auger (scroll or conveyor) then directs these solids to the underflow discharge ports. This precise separation results in two distinct outputs: the heavy phase, also known as the underflow or cake, and the lighter phase, referred to as the overflow, centrate, or effluent.

Elgin’s dewatering centrifuge technology is your solution for reliable, efficient separation processes, maximizing recovery, and improving operational efficiency.

A decanter centrifuge is a mechanical device used for the separation of solids from slurries in many industrial processes. In oil well drilling, a centrifuge is used to condition drilling fluids by dividing the fluid into high-density and low-density streams, permitting one to be separated from the other. The division is achieved by accelerated sedimentation. As the drilling fluid is passed through a rapidly rotating bowl, centrifugal force moves the heavier particles to the bowl wall, where they are scraped toward the underflow (heavy slurry) discharge ports by a concentric auger, also called a scroll or conveyor, which rotates at a slightly slower rate than the bowl. The separation of the heavier particles divides the processed fluid into two streams: the heavy phase, also called the under-flow or cake; and the lighter phase, which is called the overflow, light slurry, effluent, or centrate.

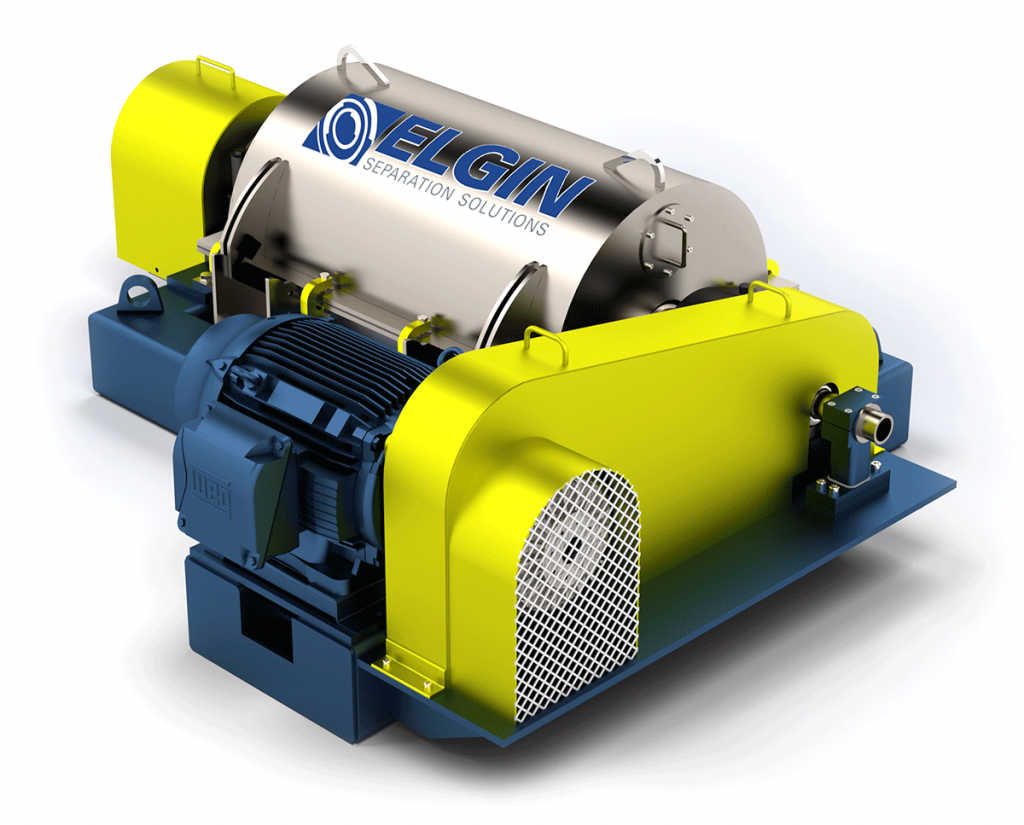

High-Speed Decanter Centrifuge

40 GPM up to 300 GPM Centrifuges

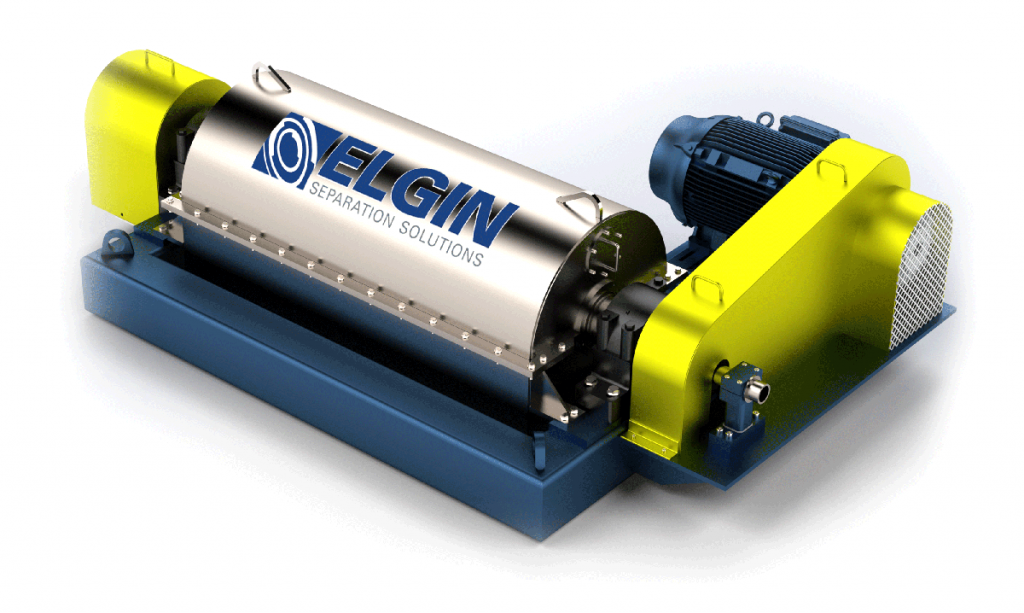

500 GPM up to 600 GPM Centrifuges

Low-Speed Decanter Centrifuge

BYRD™ Style Centrifuges

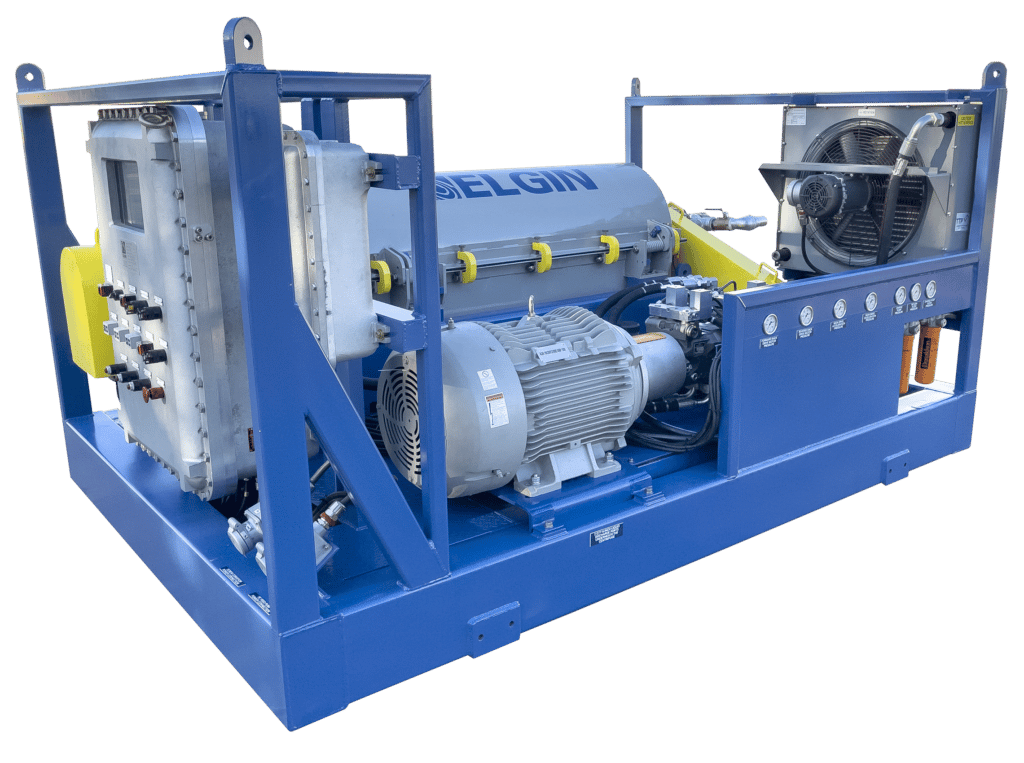

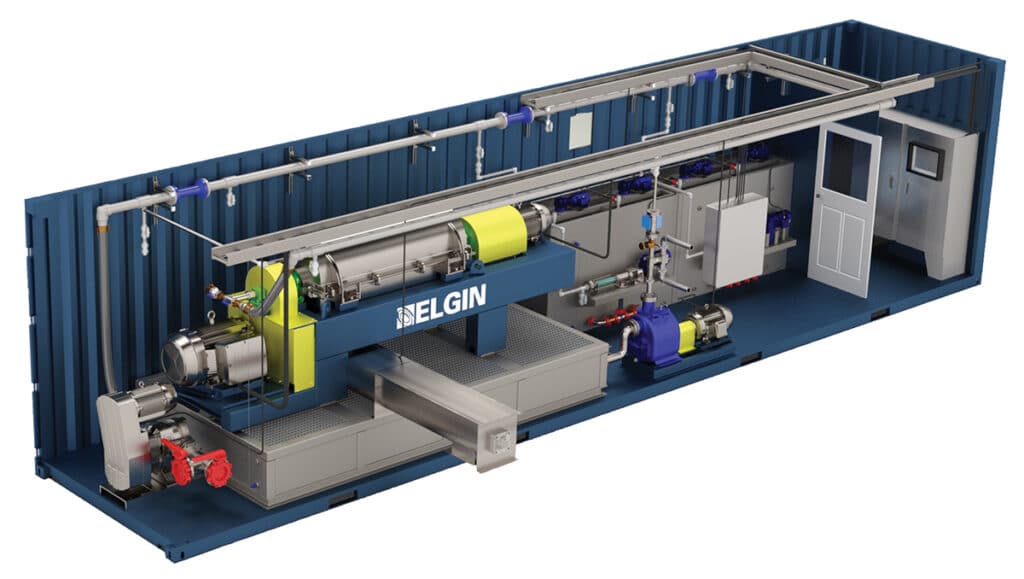

Looking for Turn-Key Decanter Centrifuge Solutions

In addition to manufacturing a complete line of decanter centrifuges, Elgin offers mobile turn-key solutions that minimize space and maximize dewatering operations. Our in-house engineering team can design the perfect trailer mounted or containerized system for any operating requirements.